Assembling and testing electronic components on small PCBs is a critical process in electronic design and production. Because electronic devices continue to shrink, the need for high quality small PCBs grows quickly. This board is used in items that can be worn, portable medical equipment, concise consumer gadgets, and more.

In this detailed guide, we will discuss the most frequently asked questions about small PCB assembly and testing. You will learn the importance of a miniature board, how to handle the assembly process, and various methods for reliable testing.

Why is small PCB important?

Small PCB plays a major role in modern electronics where compact size and lightweight form factors are very important. Whether it’s smart watches, fitness tracking, or smart home sensors, space is always limited. Miniature PCB allows to match the complex electronic function into this small cover.

But this is not just about saving space. Small PCB often increases signal integrity by reducing the length of the signal path. This is very helpful in high -speed applications. In addition, they reduce the capacitance and parasitic inductance, which improves performance in the analog circuit and RF.

In addition, small PCBs contribute to overall system efficiency. They use fewer materials, require less power, and simplify thermal management when designed correctly. With all these benefits, it is not surprising that assembling and testing small PCBs has become a special field in making electronics. Here are the main motherboards used on mobile phones:

How do you test the small circuit board?

Testing a small circuit board involves several steps, each adjusted to ensure functionality and identify defects before the board is installed in the final product. The main challenge lies in a limited real estate, which makes access and investigation more difficult. However, the following steps are usually used:

1. Visual inspection

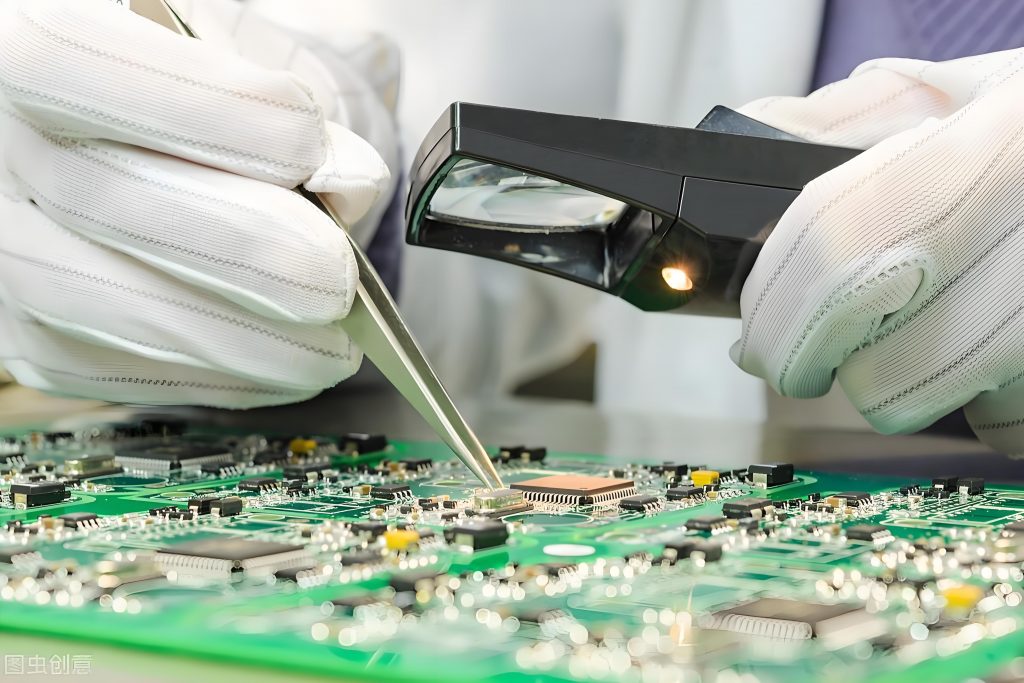

Start with close-up inspection, using an enlargement or microscope. You’re looking for:

- Soldering bridge

- Tombstoned component

- Wrong polarity

- Part that is cracked or lost

2. Examination of continuity and resistance

Use a multimeter to test continuity along copper traces. Any open paths can show manufacturing errors, such as incomplete etching or damaged solder connections.

3. Power-on testing

After you confirm there are no shorts, apply the power to use a bench supply. Use the current settings limited to avoid damage to board in the event of an error. Confirm that voltage design specifications (for example, 3.3V, 5V).

4. Examination of functional components

Activate the board subsystem one by one. For example, if there is an LED or sensor, triggers them with known inputs and checks the response.

5. Oscilloscope or Logic Analyzer

In digital systems, probe clock signals, data buses, and communication paths (such as I2C, SPI, or UART). On analog boards, check the quality and frequency of the waveform.

How do you assemble electronic components on a small PCB?

Assembling electronic components on small PCBs involves the right coordination between manual work and machine automation. Small PCB usually uses Mount Surface (SMT) technology, although some components through the hole may still be involved. You can follow the steps below to assemble components on your PCB.

1. Work space preparation

Make sure the work environment is safe ESD. Use the wrist straps, antistatic mats, and proper lighting. A clean environment reduces the risk of contamination and improves the quality of solder.

2. Pasta Stensile and Solder Applications

Use a laser-cut stencil to accurately apply solder solder on each bearing. This ensures that the component receives the right amount of solder, which is very important for small pads.

3. Pick-and-Place process

The surface installation component is placed using tweezers (manual) or pick-and-plate (automatic) machine. For very small boards, the manual method often occurs in low volume running.

4. Solder Reflow

After placement, the PCB passes through the reflow oven where the solder paste melts and hardened, binding the components safely. Reflow temperature profile must be carefully controlled.

5. Inspection and touch-up

After soldering, the council is examined under magnification. Cold connections, solder bridges, or shifted components are corrected using iron solder fine-pip or hot air tools.

6. Solder through a hole (if applies)

If your design uses a connector or switch, it will be added next. Put it in the board and hold the hand from the bottom side.

7. Final cleaning

Any flux residue that remains after solder must be cleaned with alcohol isopropil or PCB cleaning solution. This prevents corrosion and increases reliability.

How do you test the components on the PCB?

After the PCB is assembled, testing individual components confirms that they function and are connected properly. You don’t have to always have to delete the parts of the board.

Test General Components:

- Resistor: Measure the resistance value in all components with a multimeter.

- Capacitors: Use the capacitance meter or LCR meter. Electrolytes must be tested for leakage or swelling.

- Diode/LED: Use the diode mode to check the front voltage. LEDs will shine a little when working.

- Transistor: Use a component tester or check the base of the base-emitter with a multimeter.

- Integrated Circuit: for complex ICs, test power and soil PIN, and validating input/output behavior using scope.

Note: Some components can provide inaccurate reading in the circuit due to parallel paths. If the reading is questionable, one foot desolder and more test.

What are the 7 Types of PCB Testing Methods?

1. Visual inspection

Used in initial quality checks. Technicians or AOI systems look for defects that look like misalignment, bad solder, and missing parts.

2. Circuit testing (ICT)

A bed-of-nails fixture investigates the test point on the PCB. This checks resistance, capacitance, and signal path individually. Best for high volume manufacturing.

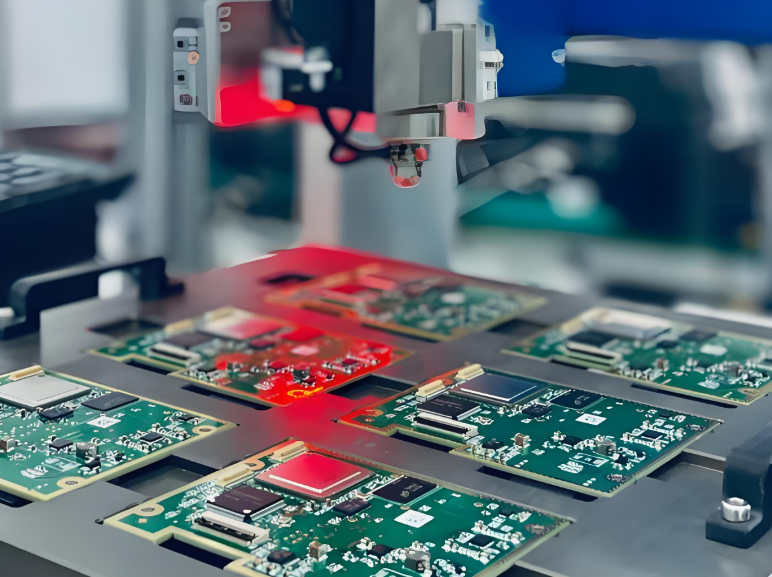

3. Flying Probe Test

Non-mixed alternative for ICT. Probe moves automatically to check the test point. Suitable for prototypes and small production processes.

4. Functional testing

Simulate real world operations. The input is applied, and the output is measured to ensure that the board functions as expected.

5. Testing the boundary scanning

Used for ICs that are packaged like BGAS. Testing internal connections and inter-chips communication using a special interface (JTAG).

6. Burn-in testing

Apply power for a long time in stress conditions. Helps detect initial life failures or unstable components.

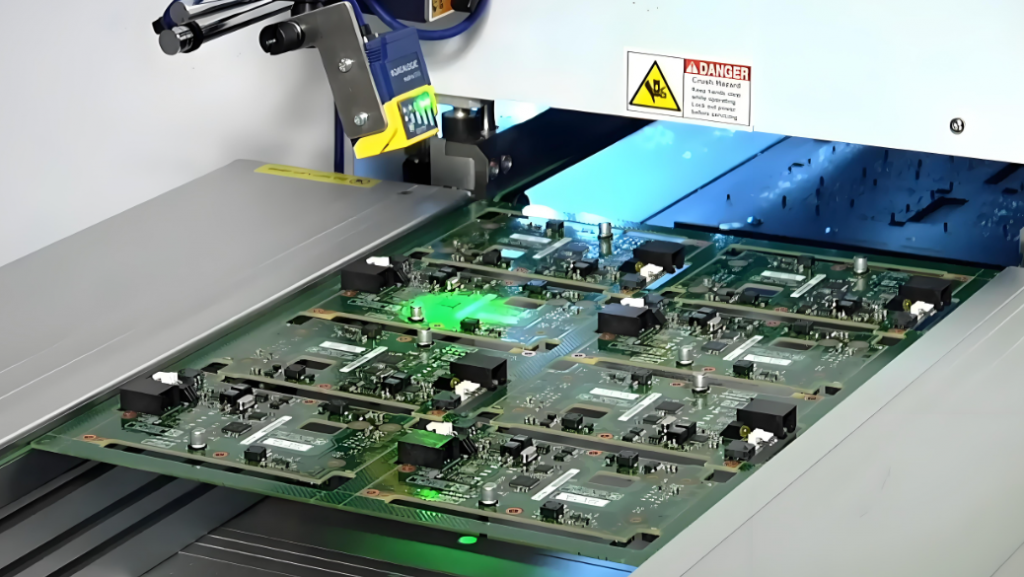

7. Automatic Optical Inspection (AOI)

A high -speed camera scans the board for defects after assembly. The AOI system compares images with gold boards and flag incompatibility.

How do you find a bad component on the circuit board?

Finding the wrong component on a small PCB is the detective work part, some experience. This is a logical way to do this:

1. Visual instructions

The burning area, cracking package, or leaky electrolyte is a red flag. Look for the physical part that looks physically damaged or changes color.

2. Examination of voltage

Measure the voltage throughout the IC PIN and Power Rail. An unexpected decline can point to a short capacitor or a wrong regulator.

3. Thermal inspection

Use the thermal camera or touch enough carefully. Heating abnormal components may be abbreviated internally.

4. Signal search

Use the scope or analysis of logic to track where the signal stops behaving correctly.

5. Component testing

Compare the reading of the part suspected of the values that are well known. Exchange parts if needed to confirm suspicion.

How do you identify electronic components on the circuit board?

Understanding how to identify components on PCB helps in repair, testing, and inverted engineering. Here are some methods that can help you identify components:

- Look at Silkscreen: Reference designers such as R5 (Resistor), C3 (Capacitors), U2 (IC) help find parts quickly.

- Check the value: Print numbers often reveal resistance, capacitance, or voltage rating.

- Use the data sheet: For ICS and Transistors, the section number can be searched online for specifications and pouts.

- See Schema: The design file provides a complete map of how everything is connected.

- Use component testers: This handheld device can identify unknown parts and help verify the PIN function.

About the best technology

The best technology is the leading PCB producer and assembly in China, offering full service solutions for small PCB fabrication, SMT assembly, and functional testing. We provide:

- PCB prototype and mass production

- Turnkey assembly with DFM support

- Functional testing and in the circuit

- Full trace through the mes system

- Quick Quotes and Professional Engineering Suggestions

If you need reliable partners to assemble and test PCBs, reach the best technology at this time.

Common faq about pcb

1. Can I assemble a small PCB at home?

Yes, with the right tools such as solder iron, tweezers, enlargers, and steady hands, you can assemble a small PCB manually.

2. What is the safest way to test the new PCB?

Start with a multimeter check for shorts, then use a bench power supply with a current limit to test in a controlled condition.

3. Can I use AOI to run low volume?

Manual inspection is more cost -effective for low volume, but the AOI desktop system is now affordable for small laboratories.

4. How do you avoid polishing errors on a small PCB?

Use stencils even for pasta applications, enlargement to check, and reflect the oven with the right temperature profile.

5. Do I need a probe test or fly?

ICT is better for big batch. Flying probe is ideal for making prototypes or small batch production without special equipment.

Tags: Assembling and testing electronic components on small PCBs, PCB assembly

This entry was posted on Thursday, June 12, 2025 at 17:09 and submitted under the best PCB, BestTPCB, FAQ, PCB News, PCB Technology, PCBA. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-06-15 10:15:13.