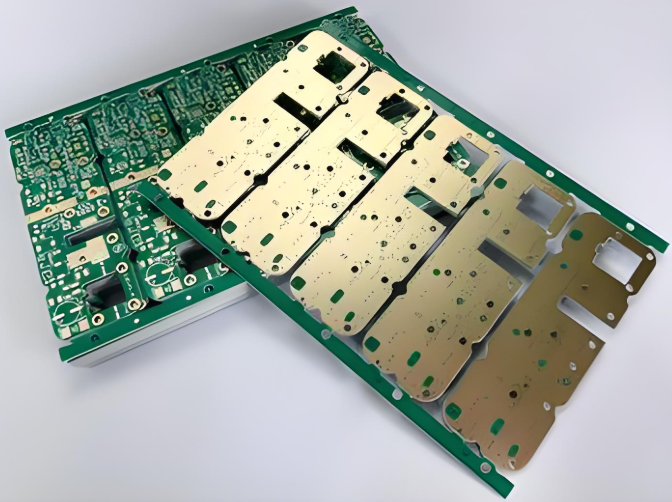

Rogers RO4350B is one of the most popular PCB materials used in high frequency applications today. If you design a circuit that requires a stable performance at the GHz level speed, this material is often prominent. In this blog, we will explore what the RO4350B is, what is made, the thickness available, and why it is preferred than other materials for high frequency PCB designs.

What is Rogers RO4350B material?

RO4350B is a type of high frequency laminated developed by Rogers Corporation. This is engineered for performance in RF (radio frequency) and microwave application, offering superior electrical characteristics compared to standard FR-4. Unlike generic epoxy-based materials, the RO4350B uses hydrocarbons-ceramic composition that maintains low signals even at high frequencies.

This material combines PTFE’s electricity performance (usually used in the upper class RF application) with FR-4 manufacturers, making it a cost-effective and reliable choice for high-speed design.

Made of what material Rogers?

Rogers material, including RO4350B, is made of hydrocarbon resin with ceramic fillers and reinforced with woven glass. This composite structure provides excellent mechanical stability and consistent dielectric properties.

Unlike traditional PTFE -based laminates, Rogers materials such as RO4350B do not require special handling during PCB fabrication, which saves time and costs. Rogers material is engineered to balance the electricity performance with ease of manufacturing, which is very important when producing high frequency PCBs on a scale.

RO4350B Dielectric constant

Dielectric constant (DK) is an important factor in high frequency PCB material, because it affects the speed of signal and impedance control. The usually dielectric RO4350B constants 3.48 ± 0.05 on 10 Ghzwhich is stable and can be predicted at various frequencies and temperatures.

Frequency and temperature consistency ensures that the transmission channel behaves as expected, which is very important in the RF circuit, micro wave devices, and antenna structure. Stable DK also simplifies impedance control and reduces the risk of signal and distortion reflection.

What is the Standard RO4350B thickness?

PCB RO4350B is available in several standard thicknesses to meet various design and performance requirements. General options include:

- 0.254 mm (10 million)

- 0.508 mm (20 million)

- 0.762 mm (30 million)

- 1,524 mm (60 million)

This thickness allows designers to choose the best piles for impedance control, thermal discipline, and mechanical strength. Depending on your signal layer, the distance of the soil layer, or copper weight, one of this thickness is likely to be in harmony with the needs of your project.

RO4350B Data Sheet

Before choosing material for your high -speed digital RF or PCB, it is important to understand technical specifications. The following is a summary of the most important values of the RO4350B data sheet:

| Owned by | Typical value | Conditions / test notes |

| Dielectric Constant (DK) | 3.48 ± 0.05 | @ 10 GHz (Z axis) |

| DISCIPATION FACTORS (DF) | 0.0037 | @ 10 GHZ |

| Volume resistivity | 1.7 Ã- 10â ¸ mî © Â · cm | ASTM D257 |

| Surface resistivity | 4.4 Ã- 10 · Mî © | ASTM D257 |

| Electric power | > 800 V/mile | ASTM D149 |

| Dielectric damage | > 40 kV | ASTM D149 |

| Thermal conductivity | 0.69 W/Mâ · K | ASTM D5470 |

| Thermal Expansion Coefficient (CTE) | 11 ppm/â ° C (x, y)/32 ppm/â ° C (z) | -55 ° C to 288 ° C. |

| Glass transition temperature (TG) | > 280 ° C (no TG specified) | Thermomechanical Analysis |

| Decomposition Temperature (TD) | ~ 425 ° C. | TGA method |

| Solder Reflow Resistance | Very good | No delamination or blisters |

| Tensile modulus | 1.4 Ã – 10â ¶ psi (xy) | ASTM D638 |

| Flexible power | 20,000 PSI (Typical) | ASTM D790 |

| Peel strength | ‰ ¥ 1.1 N/mm | IPC-TM-650 |

| Modulus Young | ~ 10 GPA | Estimated from the voltage curve |

| Humidity absorption | 0.06% | ASTM D570 |

| Density | 1.86 g/cmâ³ | ASTM D792 |

| Flammable ranking | UL 94 V-0 | Ul 94 |

| Water absorption | <0.1% | Excellent water resistance |

| Material composition | Hydrocarbon resin containing ceramics + glass fiber | Non-PTFE-based |

| Halogen free | Yes | Rohs & Reach Notes |

| Available copper foil | 0.5 ounces, 1 ounce, 2 ounces (18 μm, 35 μm, 70 μm) | The option that is rolled and deposited electro is available |

If you need a complete official data sheet in PDF format, you can also ask for it from the best technology along with a quote for your project.

How much does Rogers PCB cost?

Compared to FR-4, the price of the Rogers RO4350B is higher because of its premium performance. The average, RO4350B material can be worth between $ 8 to $ 25 per square foot, depending on the thickness, copper weight, and supplier volume. Complete PCB fabrication using RO4350B usually produces a price of 20- € “50% higher than using standard FR-4, mainly due to material costs and additional processing steps.

However, when you work with high frequency applications – such as 5G, radar, or satellite communication € “Increited signal integrity and reduction of losses often justify additional costs.

What is the difference between RO4003 and RO4350B?

Both Ro4003 and RO4350B are part of the high frequency laminated series, but they have subtle differences:

| Feature | RO4003C | RO4350B |

| Dielectric constant | 3.38 | 3.48 |

| Tangent loss | 0.0027 @ 10 GHZ | 0.0037 @ 10 GHZ |

| Fire ranking | Non-ul is assessed | UL 94 V-0 |

| Cost | Slightly lower | A little higher |

| Process compatibility | Standard PCB process | Standard PCB process |

RO4003 is more suitable for applications where the sensitivity of the cost is very important and the ranking is not needed. RO4350B, on the other hand, provides a better fire ranking and a slightly better mechanical property, so it is a preferred choice for commercial applications or defense levels.

Why choose RO4350B as a high frequency PCB material?

High frequency PCB, also known as RF PCB, refers to a special circuit board with a relatively high electromagnetic frequency. This PCB is mainly used in high frequency planes (> 300 MHz or wavelength <= 1 meter) dan gelombang mikro (> 3 GHz or wavelength <= 0.1 meters). If you design a high frequency PCB, choosing the RO4350B gives you the best of the two worlds: high performance and ease of fabrication. This is why many engineers choose this material:

- Low dielectric loss helps reduce signal attenuation.

- Stable dielectric constant ensures consistent impedance.

- Thermal management is better than FR-4.

- UL 94 V-0 API resistance, which is very important for safety.

- Compatible with standard FR-4 processing, so there is no need for special TEFLON tools.

All of these features help maintain signal quality in applications such as RF transmitters, satellite recipients, and high -speed digital circuits. So, even if the price of the RO4350B is slightly higher, often more cost-effective than consuming performance problems caused by suboptimal materials.

High Frequency PCB Design Guidelines

When working with the RO4350B PCB material, remember the following design practice to get the best results:

1. Control impedance: Use the right width-up and trace calculator for accurate routing 50î © or 75î ©.

2. Minimize VIAS: Each through introducing inductance and can distort signals at high frequencies.

3. Short trail length: High -speed signals must have the shortest path.

4. Right foundation: Always include continuous land fields to reduce EMI and increase the return path.

5. Avoid sharp angles: Use a 45 degree or curved trail, not a 90 degree angle.

6. Use differential pairs: For high -speed interfaces such as USB or LVD, pairs combined with strictly reduce crosstalk and maintain signal integrity.

Combining these techniques with the natural performance of the RO4350B helps you open superior RF performance without increasing the complexity of fabrication.

Why the best technology is your reliable PCB RF manufacturer?

In the best technology, we specialize in making high frequency PCBs using premium materials such as RO4350B, RO5880, RO4003C. With ISO certification, we are equipped to serve industries ranging from automotive and medical to aerospace and communication. Whether you develop a high reliability prototype or large-scale production, you can rely on us as a reliable PCB & PCBA One-stop PCB partner.

We offer:

- Tight impedance control with sophisticated test equipment

- Fast prototype and flexible volume production

- RO4350B prices are competitive with guaranteed traction

- Expert technical support for material layout and selection

- No MOQ needs, 1 part is available too

- 5 Year Quality Assurance, Free Re -Work and Functional Testing

- FREE DFM Inspection

If you want to produce a reliable high frequency PCB, you are in the right place.

FAQ

1. Is the RO4350B suitable for Multilayer PCB?

Yes, the RO4350B is usually used in multilayer designs for RF and microwave applications. It offers a stable performance in a single and multi-layer pile.

2. How is the RO4350B performance at 5GHz or higher?

This maintains low losses and consistent DK values even at frequencies above 5GHz, making it reliable for 5G circuits and radar.

3. Can the RO4350B be used with FR-4 in a hybrid pile?

Yes, that can. Many engineers use RO4350B for RF and FR-4 layers for power/control layers to reduce costs.

4. How old is the storage of RO4350B material?

Stored in the right condition, it has a long shelf life â € “is usually more than a year without degradation.

5. Do I need a special PCB fabrication for RO4350B?

Unlike PTFE -based materials, the RO4350B is compatible with a standard PCB fabrication process, which simplifies the manufacture.

Contact the best technology today to get offers or talk to our engineers about your RF design needs.

Tags: Ro4350B, RO4350B Datasheet, RO4350B Dielectric Constant, RO4350B PCB Material, RO4350B thickness

This entry was posted on Friday, July 4, 2025 at 17:43 and submitted under the best PCB, BestTPCB, Design Guide, FAQ, PCB News, PCB Technology, RF Council. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime