Damage to the circuit board occurs for various reasons of heat, humidity, the aging, or physical stress. But with the right knowledge and tools, repairing PCBs is completely possible. Is it a simple home device or AC control board, identifying this problem early helps reduce costs and prevent deeper damage.

If you deal with HVAC units, industrial equipment, or sensitive medical devices, work with professionals. The best technology supports customers around the world with reliable PCB production and testing. From a standard single layer board to complex multilayer and ceramic solutions, we are committed to high performance and long -term quality.

What are the most circuit problems?

Most of the circuit board problems are caused by heat, humidity, surge in power, dust, and aging. These problems affect the board slowly from time to time or at once. Heat, in particular, is a silent killer. When the components become too hot, they wear out faster. Solder joints also become weak. Over time, the council may stop working even if there is no damage.

Humidity is another hidden threat. If water or humidity enters the board, it can cause corrosion. Corrosion undermines copper traces and makes a weak connection. If you are in a humid climate or near the sea, your electronics may wear faster except sealed correctly.

Another problem is physical stress. If the board is bent or many shaken, microcracks can appear. This crack is difficult to see but can break the connection on the board. Finally, the signal cannot travel properly, and the council may fail.

What is usually bad on the circuit board?

Some parts of the circuit board are more likely to fail than others. Capacitors are one of the most common troublemakers. They are often found in the power supply, and over time they dry or leak. When that happens, your device may stop burning, or maybe behave strangely.

Resistors can also be burned, especially if there is a short circuit. When a resistor fails, often becomes black or broken.

Integrated Circuit (IC) is another weak point. These chips control important functions. They are small and sensitive. A small voltage surge can damage it instantly.

Solder joints are also a common problem. Over time, this joint can crack. This causes the component to lose contact with the board. Repetition usually solves this problem, but only if the council is not too damaged.

What will cause the circuit board to burn?

The burning circuit board is a serious problem. It usually happens because:

- Short circuit

- Power supply problems

- Failure of components (such as transistors or failed voltage regulators)

- Poor PCB design or low quality manufacturing

- Buildup of dust that causes a bow or hotspot

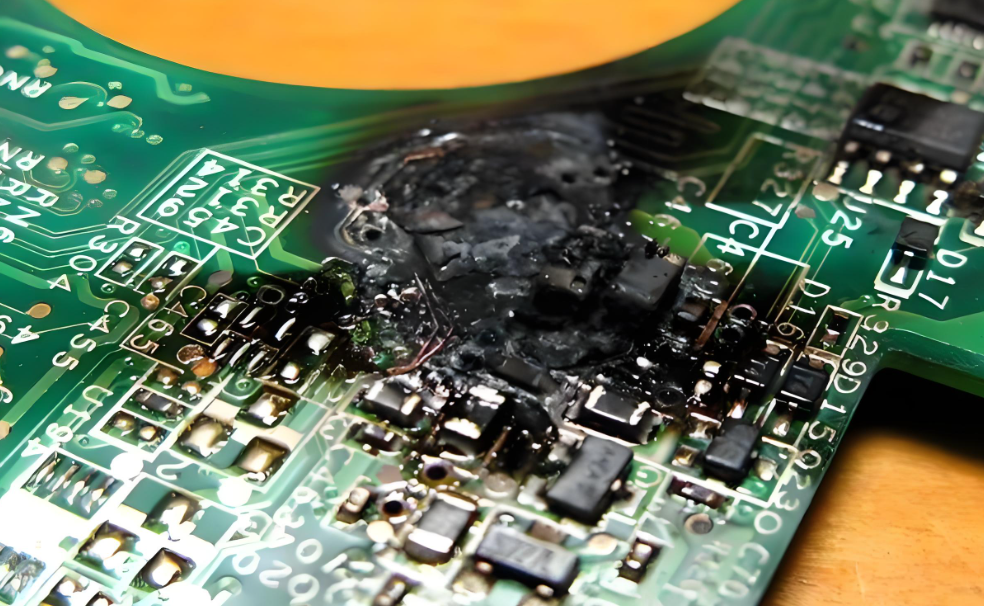

Signs of burn, disbursement, or burning odor are signs of severe damage to the board. In some cases, PCB repair is still possible. But if the internal layer is affected, the replacement may be a choice.

How do you find out whether the circuit board is blown up?

It is not always easy to find out whether the board is blown just by looking. But there are several signs to check:

1. Physical instructions

- Burning marks or dark spots

- Swollen or leaking capacitors

- Cracked chips

- Melted area or damaged traces

2. Electric behavior

- This device won’t turn on

- It is in power but acting erratically

- The device stops working

3. Test with tools

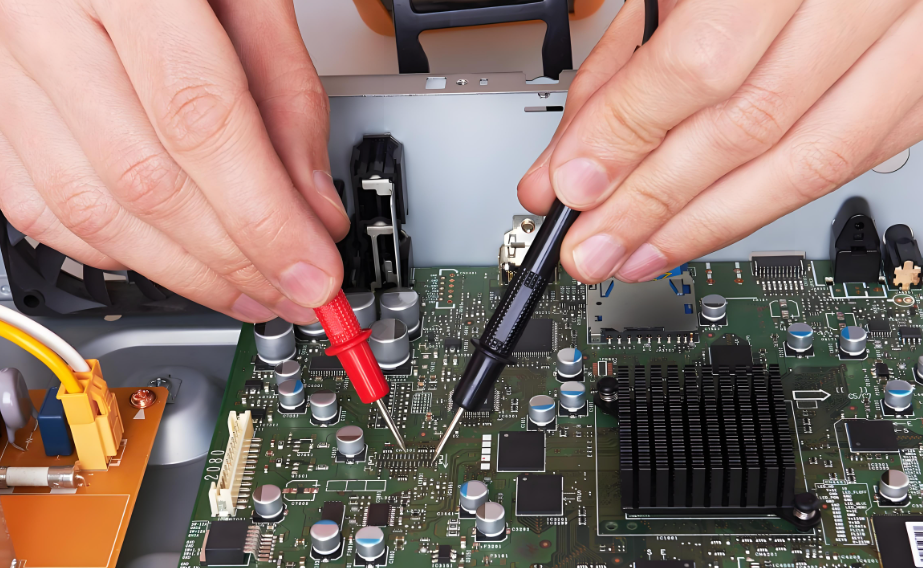

- Use a multimeter to check voltage and resistance

- Check continuity to find a damaged path

- Lack of signal or strength at the test point means something wrong

If one of these signs appears, the board might be blown up. Depending on damage, the cost of repairing the PCB board can vary from low to high.

How long has the circuit board to survive?

PCB that is made well can last 10 to 20 years. Some last longer if stored in a place that is clean, cool, dry. But others failed in just a few years. It depends on:

- Component quality

- How hot the board is

- How clean the environment

- How often the device is used

For example, the control board in the AC unit may last 10 years 15 years. But if exposed to heat and dust, failure can occur faster. Maintaining regular cleaning and maintenance helps extend life. And replace outdated capacitors and clean dust every year to prevent general failure.

What does PCB actually mean?

The term PCB improvement means improving any part of the circuit board that no longer works. It might include:

- Replace damaged components

- Repairing traces or damaged cushions

- Fix a bad soldering connection

- Clean the dirty or corroded part

PCB improvement does not always require further skills. If you understand the circuit and can use multimeter and solder iron, small repairs are possible. For more complex improvements, it’s better to visit the service center.

Is it possible to fix the circuit board?

Yes, the circuit board can be fixed. But it depends on the type of damage. If a part is damaged, it can usually be replaced. If the trail is cut, it can often be patched with jumper wire. Here are some common PCB improvement methods:

- Replacement of components: if the resistor, capacitor, or chip fail, the new desolder and install.

- Footprint Repair: Use jumper or conductive ink wire to reconnect damaged traces.

- Joint soldering repair: Reflow Old Solder or add fresh solder to a cracked connection.

- Cleaning corrosion: Use alcohol and brush to eliminate oxidation or rust.

Some easy improvement. Others, such as repairing damaged inner layers, may not be possible without factory tools. For home users, many improvements are possible with basic PCB repair tools. At most technology, we offer a free PCB board repair service if your board is bad during operation or assembly, we can fix it for you and free.

How much does it cost to replace the AC control board?

The cost of repairing PCB AC or replacement costs depends on the model and brand of the board.

1. Simple PCB AC Repair

If only one or two poor components, a technician can charge $ 50.

2. Replacement of PCB AC

If the board is really fried or has a rare error, full replacement may be needed. It can be charged:

- $ 150â € “$ 250 for housing units

- $ 300â € “$ 400 for high -class or commercial ACS

Workers may be more extra if the unit is difficult to open. In some cases, it’s cheaper to improve the board using local services with the experience of repairing PCB AC.

PCB repair tools you may need

To fix the circuit board, you don’t need a complete lab. The small kit with the right tool is enough for most work. The following is an important PCB repair tool:

1. Solder Iron: Must be owned to replace the components

2. Reduced pumps or braids: To delete old solder

3. Multimeter: To test the voltage and check the open circuit

4. Tweezers and magnifying glass: Help to handle small parts

5. Hot air re -work station: Required for Surface Installation Parts (SMD)

6. PCB holder or clamp: Keep your board stable while working

7. isopropyl alcohol and brush: To clean dust or corrosion

With exercises, many home users can fix basic problems. Make sure to work slowly and carefully.

Can you do an PCB AC fix yourself?

If you have knowledge of electronics and the right tools, you can fix your own AC control board. You can:

- Change the burning capacitor

- More loose joint loose

- Clean the board to remove dirt or corrosion

But there is a risk. The AC board often controls the high voltage. Errors can damage the system – or cause injury. You should not try to improve PCB AC if:

- You are not used to electronics

- The damage looks severe

- You don’t have the right tools

In this case, it is better to contact your PCB manufacturer or look for workshops that meet your local requirements.

How to prevent damage to the circuit board?

Repair is good, but prevention is better. You can reduce the possibility of needing PCB improvement by:

- Keep electronics clean and dry

- Avoiding a surge in power with surge protectors

- Ensure appropriate ventilation to reduce excessive heat

- Installation board safely to avoid mechanical stress

Schedule regular inspection and cleaning, especially for industrial systems and HVAC

Prevention steps are usually cheaper than dealing with exploding boards.

When to replace instead of repairs?

In some cases, fixing the board makes no sense. You have to replace it if:

- Damage includes a large area

- The council has many parts that are burned or damaged

- Cheaper to be replaced than fixing

- It’s hard to find a part for improvement

If your air conditioner is old and the part is rare, often smarter to increase boards and units. You will avoid repeated repair costs.

About the best technology

Best Technology is a reliable PCB manufacturer in China. We specialize in making small to medium PCB, PCB assembly, and electronic manufacturing services. As one of the suppliers of a very experienced circuit board, our products and services include various printed circuit boards such as rigid PCBs, flexible PCBs, rigid-flex PCBs, aluminum PCBs, RF microwave PCBs, high-speed PCBs, high frequency PCBs, and PCB HDI.

Aside from being an experienced print circuit board manufacturer, the best technology also provides Turnkey assembly, component sources, box assembly, PCBA testing, and complete electronic testing and assembly. We are a one -stop PCB manufacturer dedicated to fulfilling all requests for making your PCB board.

FAQ

1. What is the meaning of PCB improvement in electronics?

This refers to repairing damaged components, traces, or solder connections on the circuit board to restore functionality.

2. Can PCBs Burn Repaired?

Yes, if the damage is limited to the outer layer and does not affect the inner trail, it can often be repaired.

3. How much does it cost to repair the PCB board?

This ranges from $ 50 to $ 150 depending on the level of damage and labor involved.

4. What tools are used for PCB repair?

Common tools include soldering iron, multimeter, hot air weapons, tweezers, and despair.

5. What is the improvement of PCB AC commensurate?

If the board is rare or expensive, yes. But sometimes, full replacement is more cost -effective.

Tags: PCB board repair costs, what is the most damaging the circuit board

This entry was posted on Wednesday, July 2, 2025 at 18:21 and was submitted under Uncategorized. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-07-02 13:25:08.