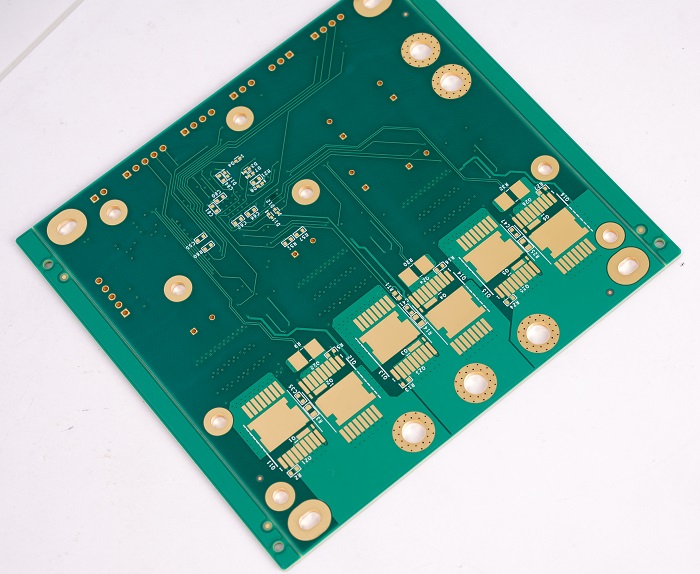

The quality of PCB PCB pad is very important for each printed circuit board to perform well in the field. In this blog, we especially explain what is PCB copper bearings, its types, surface layers, functions, general peeler problems, and practical improvement and material selection solutions for reliable manufacturing.

Have you ever experienced this nightmare and headache in your project?

- Mechanical damage and mechanical voltage problems?

- Material problems and processes cause peeling PAD?

- Poor solder and thermal stress?

- Design defects and manufacturing?

Here are the solutions and steps recommended by the best technology.

- Optimize the soldering process: Control the temperature and time of solder according to the type of PCB bearing; Use an iron and solder solder premium.

- Improve the material and process: Improve the quality of copper coils to ensure adequate adhesion between copper and resin. In addition, it is very important to improve the manufacturing process, such as lamination, etching, and coating, to ensure a strong bond between copper foil and substrate.

- Optimizing design and storage conditions: First, we must increase the distance between copper and edge foil to reduce mechanical stress and avoid too close between copper foil and edges. Second, the point is to avoid humid environmental exposure for a long time.

- Increase thermal stability of bearing: We will increase the thickness of copper foil through coating or other ways to increase thermal conductivity and reduce the impact of high temperatures localized to bearings. Finally, using quality copper foil better guarantees a great adhesion between copper and resin.

The best technology provides various types of PCBs to markets that are much larger for more than 19 years, such as PCB Bus Bar, RF Board, HDI PCB, TGB TG PCB, extra thin PCB, and others. We have a tight quality inspection system, where each manufacturing process will undergo a tight QC. If you need a PCB, don’t hesitate to write an email to [email protected] or call +86-755-2909-1601.

What is PCB copper bearing?

PCB copper bearings are conductive surfaces on print circuit boards where the soldering components. This bearing provides an electric and mechanical connection between the board and the electronic part. It is fun to know that the shape of the bearing can be round, square, or adjusted shape. It is useful to meet design demands. Extraordinary quality bearings ensure stable solder, low signal loss, and long -term stability.

In our experience in the best technology, many customers approached us after facing the bad adhesion of PAD from other suppliers. We avoid this problem before shipping through using extraordinary quality copper foil, high precision etc., and strict quality inspection.

What are the various types of PCB bearings?

It is very helpful to find out that the PCB bearing includes the following type.

- Bearing through holes: This is a drilling hole with a layered copper, which is used for components leading to pass and solder. Which provides mechanical support.

- SMD Pads: This is used in a flat copper area of the components mounted on the surface, suitable for high density circuit boards.

- Thermal assistance bearings: This is designed to control heat flux during solder to avoid excessive heat.

- Via pads: Connect the layer in a multi-layer board, generally smaller than component bearings and is important for multi-layer boards.

It is very important to choose the appropriate type of bearing, because it will affect the speed of assembly, solder strength, and integrated board performance.

SMD Pads PCB vs through holes: Which is better for your PCB?

SMD Pads PCB design is preferred in high and light density applications such as smartphones and devices that can be worn. They allow smaller boards and faster automatic assembly.

The bearing through a hole is very suitable for components that require extra mechanical strength, such as connectors or high power devices. In general, to see that hole bearings are used in places where stability is needed and SMD bearings are used in high density areas. In many projects, engineers will prefer to use hybrid designs.

What is the finish of the PCB copper pad?

Surface finishing is a layer applied to copper pads to protect it from oxidation and ensure good solder capabilities. Common surface maintenance includes HASL, ENIG, OSP, IMMERSION TIN, Silver, and hard gold coating. For PCB copper pads, most of the enig is used for its smooth surface, oxidation resistance, and long life.

The best technology uses enig or hard gold coating for applications that require high reliability, such as aerospace, to ensure high-quality soldering performance even after months of storage.

What is the function of PCB Cu Pad?

PCB Cu Pad is not only an electric connection point but also the mechanical repair point of the component. This maintains the efficiency of signal transmission and maintains a stable performance of components in vibrational situations or mechanical pressure. It is fun to know that there is no reliable bearing, even the most sophisticated circuit design, can fail.

Why PCB Copper Pad Peels?

It is very valuable to find out why PCB Copper Pad Peels.

- One common reason is the bad adhesion between copper and substrate. This can happen if there is not enough laminated pressure or if the surface is contaminated.

- The second important point is that the exclusive heat of solder will cut the bond power.

- The third important reason is that the mechanical stress is too high in assembly or the process of repair, What’s interesting is the bearing from lamination.

It is known that the PCB Copper Pad Peels will increase the difficulty of re -work and cost. The best technology prevents this problem through controlling process temperature, using professional quality substrates, and making temporary skin strength tests.

3 Repairs for PCB Copper Pad Peels in Manufacturing

Based on industrial experience, here are three effective solutions:

- Improve the laminated process: Make sure the surface of the substrate is clean and use the right laminated pressure to achieve strong copper adhesion.

- Solder temperature control: Take advantage of the initial heating process to protect the pads from overheating.

- Improve material quality: Choose high -powered copper and extraordinary quality substrate to reduce the risk of PCB Copper Pad Peels.

Customer complaints are significantly reduced when the best technology applies these steps. We have received repeated orders and good project results.

How do I do the PCB copper pad repair for PCB factory?

There are several steps to improve PCB copper bearings to peel.

- The first step is to clean the damaged area.

- The second important step is to apply the appropriate adhesive or epoxy.

- The third critical point is to use copper foil pieces appropriately or compatible bearings, instead of using the original cushion.

- The last point is to ensure that the bearings that are repaired are compatible with mechanical and electricity standards.

This process can be simplified by using a PCB PAD repair kit. The best technology matches the size of the original PAD tightly and surface maintenance during the repair process. It aims to ensure that the reliability of the repaired board is the same as the original board.

How do you choose the right PCB pad material for your project?

The choice of material PAD affects conductivity, solder capabilities, and long -term performance. For most commercial boards, copper is standard because of its high conductivity. Coating or coating materials – Gold, Tin, Silver – Must match the assembly method and your storage conditions. For example, Enig is ideal for the PCB design of the SMD Fine-Pitch pads, while the hasl may be in accordance with projects that are sensitive to costs.

The best technology helps customers evaluate these factors to reduce the level of re -workmanship and extend the life of the product. If you have further questions, please contact us at +86-755-2909-1601 or [email protected].

Overall, the reliability of the PCB copper PAD becomes the center of attention in manufacturing. Every process is related to the quality of the circuit board, from the type of PCB bearing, surface treatment, and steps to overcome the problem of peeling. Producers can increase PAD exfoliation problems through proper material selection, strict process control, and decent maintenance methods. The best technology is 100 percent dedicated to break the pain point of exfoliation and re -work. With our qualified manufacturing process according to ISO standards, professional engineers, and customer’s first services, we excel in providing good quality PCB to the market. If you need to order a PCB or PCBA, tell us [email protected].

Tag: PCB copper bearing

This entry was posted on Friday, August 15, 2025 at 19:15 and submitted under the best PCB, BestTPCB. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime