Isolated metal base pcb is a type of circuit board designed for high heat dissipation. This is a metal core feature “usually aluminum or copper” is covered by a thin insulation layer and a coat of copper circuit. This structure allows heat to transfer from components quickly, making it ideal for high -power applications such as LED lighting, power supply, and automotive system.

What is IM on PCB?

STI is an abbreviation of isolated metal substrate. This type of certain printed circuit board designed to transfer heat away from high power components.

Unlike traditional boards made of FR4 or Fiberglass, PCB IMS has a metal base layer, Usually aluminum or copper. On top of this, there is a layer of thin dielectric isolation that separates metals from copper circuits. This structure allows boards to carry electrical signals while efficiently pulls heat from components.

What is the definition of PCB STI?

Simply put, an IMS PCB is a single layer PCB with metal support that provides better thermal conductivity than standard materials.

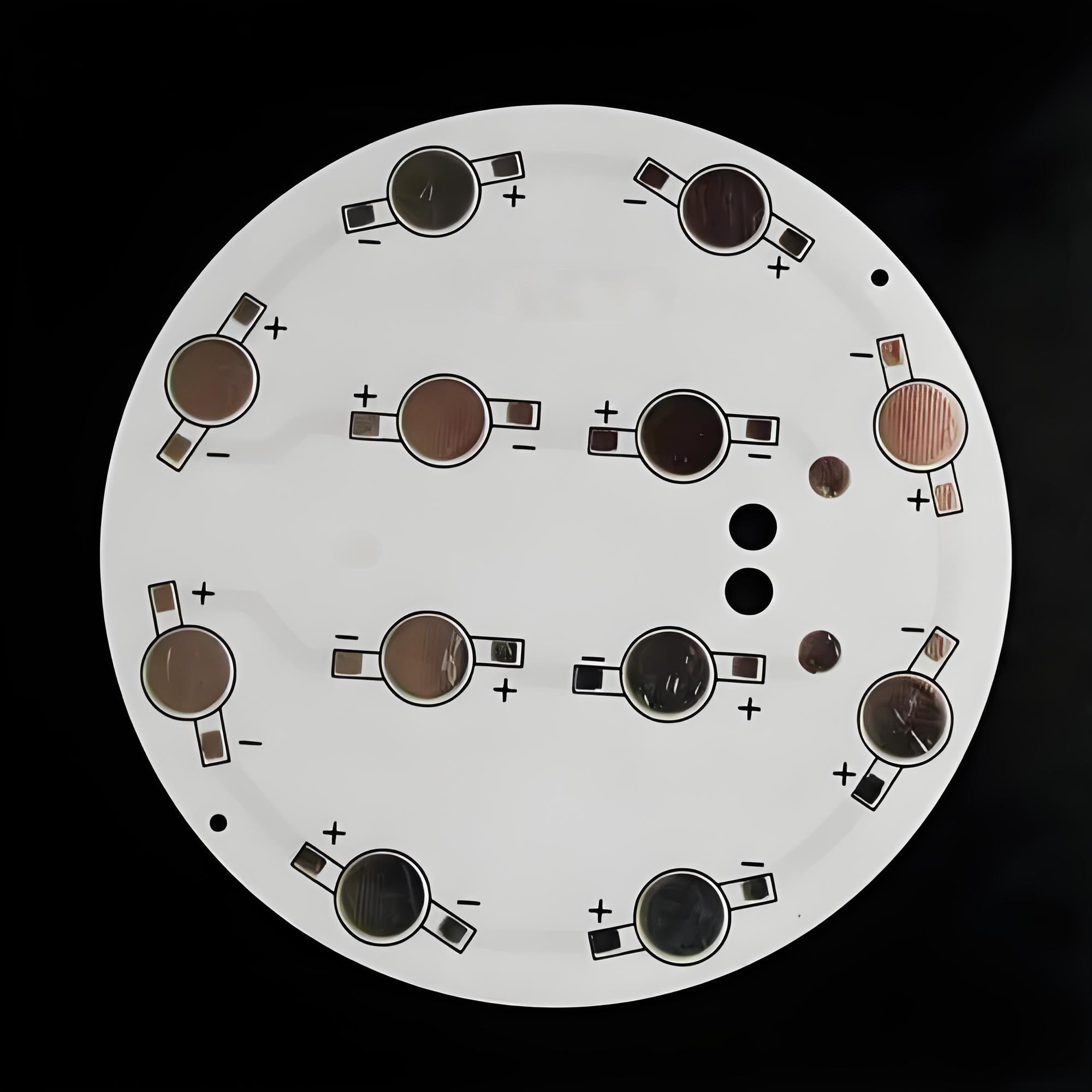

This type of board is very common in high power applications such as LED drivers, power supplies, automotive lighting, and industrial equipment.

The isolation layer, although thin, plays an important role. This ensures the function of the circuit correctly while still allowing heat to pass through the metal core. This structure like a sandwich is what distinguishes IMS PCB from standard design.

What materials are used in the production of STI PLAN PCB?

This is what enters the PCB high -performance STI board:

- Metal base layer: most common aluminumalthough copper is used in a high demand environment. Aluminum is preferred because of cost efficiency, mild nature, and good thermal performance.

- Dielectric layer: This is the heart of heat transfer. It must be thin enough to allow the thermal flow, but strong enough to hold the voltage voltage.

- Copper foil layer: Circuit layer, usually 1 € “thick 3 ounces. This is where your electronic components are connected and signal the trip.

- Surface finishing: Surface maintenance such as Enig (Electric Nickel Soaking Gold) or OSP (Organic Sutderability Preservative) ensures strong pollujausal and prevent oxidation.

On Best TechnologyWe adjust each STI board to your needs. Whether you need a basic ingredient of copper or aluminum, special thickness, or a unique final layer, we send your standard.

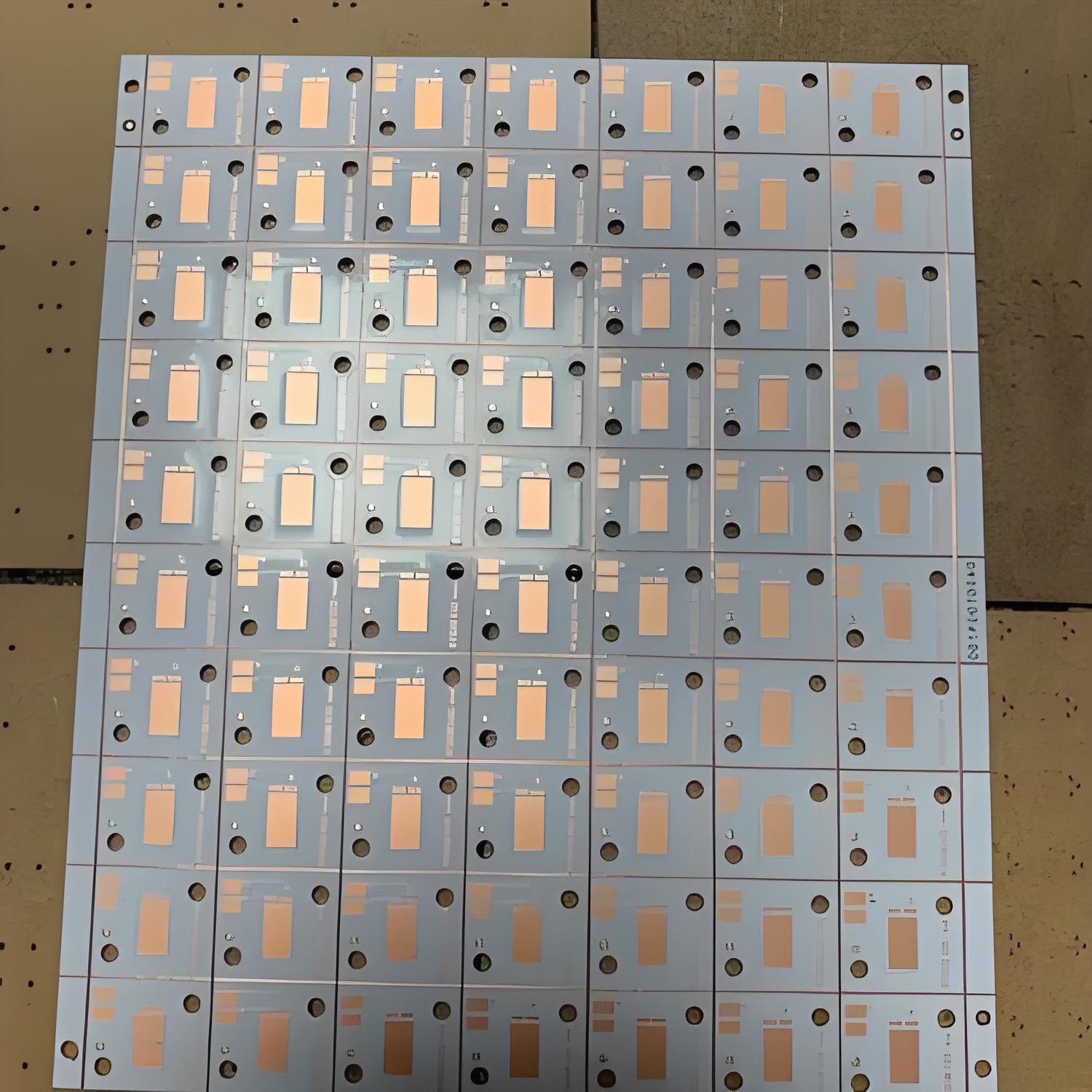

How does the STI manufacturing work?

That MANUFACTURING IMS The right and designed process. This is the way we do it in the best technology:

- Basic Preparation: We start with aluminum or copper plates with high purity. This is cleaned and prepared to delete any contaminants.

- Lamination: Dielectric material is laminated to the base of the metal. This insulation controls heat transfer and electrical insulation.

- Copper Cladding: The copper foil is applied above the dielectric. This forms the basis of your circuit path.

- Imaging and ETSA: Using UV exposure, we apply your circuit pattern. Then we tighten the excess of copper to just leave the trail you want.

- Drilling and coating: Hole for mechanical support or electric connections properly drilled and layered.

- Solder mask and finish: The solder mask is applied, followed by a final surface that matches your assembly method.

- Testing: Electric testing ensures that each circuit function is perfect. Our factory is inspection 100% before shipping.

How does STI PCB handle heat?

Beauty IMS PCB Located in their thermal path. Heat from components through copper traces to the dielectric layer, and from there, it is transferred to the base of the metal. Base, often aluminum, quickly spread and eliminate heat throughout the board or become a heat sink.

This makes the board cooler, even below the high power load.

Compared to the standard FR4 board, the IMS PCB has a thermal conductivity of up to 10 times better. This directly reduces component stress, avoiding initial failure, and increases long -term reliability.

What are the benefits of PCB STI?

- Superior heat dissipation: IMS PCB is engineered to manage heatâ € “fast and efficient.

- Compact design: With better thermal control, components can be placed closer together. This allows smaller and lighter devices.

- Longer age: Cool components last longer. That means fewer improvements, better reliability, and higher quality final products.

- High mechanical strength: The metal base increases stiffness and reduces vibration. Ideal for automotive equipment, aerospace, and outdoors.

- Cost savings from time to time: Although a little more expensive in advance, the STI board can reduce the need for extra cooling systems.

- High power density: Good for applications such as LED drivers, where a compact and strong system is a must.

In short, the IMS PCB provides power, endurance, and the perfect trio for demanding industries.

What is the PCB IMS board used for?

IMS PCB is very flexible and can be used in systems where heat and power are of concern. General use includes:

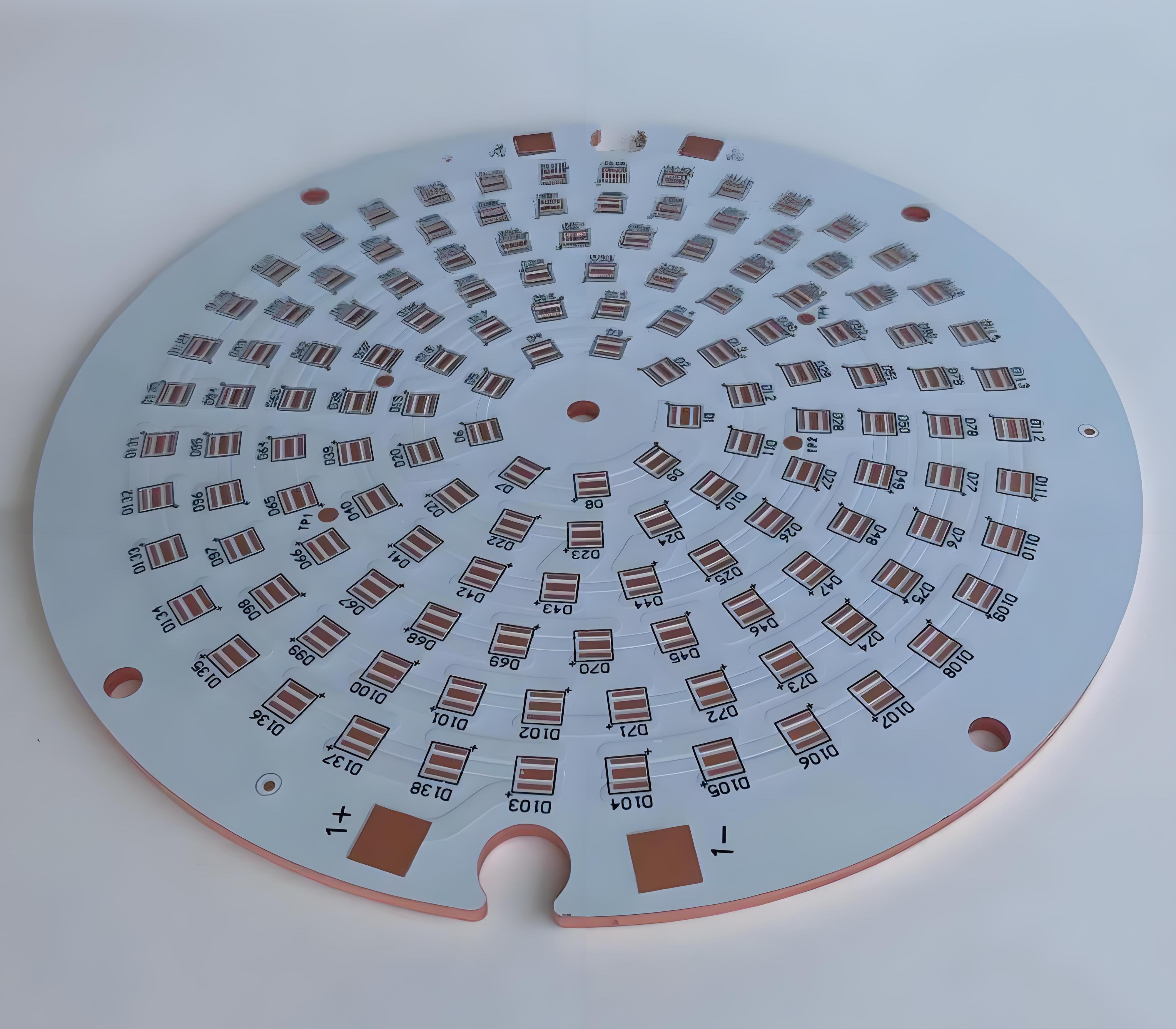

- LED Lighting Module: Street lights, automotive lights, stadium lighting.

- Power Electronics: Converters, adapters, power distribution units.

- Automotive System: Brake system, engine control unit, infotainment panel.

- Industrial Control: Motorcycle drivers, automation panels, heavy engines.

- Medical devices: Imaging equipment, surgical lighting, diagnostic system.

- Telecommunications equipment: Base stations, antennas, and signal amplifiers.

These boards shine in any place where the size of the compact and high power must live side by side safely.

What is the best PCB manufacturer?

When you search IMS BoardThe manufacturer you choose makes all differences.

Best Technology Prominent as one of the most reliable IMS PCB manufacturers in China. This is why:

- Established expertise: Since 2006, we have focused on MCPCBS and the STI board, providing uncompromising quality.

- Certified Reliability: We have certifications such as UL, ISO9001, ISO13485, IATF16949, and SGS ‘support our quality promises.

- Full Turnkey Service: From PCB design to assembly, we manage everything. This shortens the waiting time and streamlins your workflow.

- Strong factory support: Our 30,000 and 229+ factory allows large -scale production with consistent results.

- Competitive Prices: We manage the cost intelligently to give you the maximum value for your investment.

Most importantly, we believe in partnerships. Our team works closely with you, offering one-on-one help, special solution, and a 48-hour technical response policy.

Conclusion:

Whether you design a concise LED module or build an industrial power unit, the STI board offers the reliability and performance you need.

As a professional IMS PCB Manufacturer, Best Technology Can provide expertise, services, and trusted quality. With more than 19 years of experience, comprehensive certification and customer’s first philosophy, we are proud to be a reliable supplier for all your IMS council needs.

Is there a project in mind? Reach us today at [email protected]

Tags: IMS Manufacturing, IMS PCB Definition, IMS PCB Manufacturer, Isolated Metal Base PCB

This entry was posted on æÿœœä¸ €, 21 7 æœatra, 2025 at 5:58 ¸ ‹Å ˆ and submitted under MCPCB, Metal Core PCB, PCB technology. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime