China Heavy Copper PCB is not just about thicker copper layers. This is a complete solution to manage high currents, heat, and mechanical pressure in demanding an electronic system. For engineers and buyers who need reliability, fast prototypes, and risk reduction, heavy copper PCBs from Chinese producers are trusted to be important. This article dive into what makes them special and how to choose the right partner for your next project.

The best technology is one of the leading heavy copper PCB manufacturers in China, providing pre-sales support, fast prototypes, and assembly services. We believe that the making of a fast prototype, extraordinary quality, Turnkey EMS PCB solution, and efficient shipping is a prerequisite for us to “prove long -term competitiveness and win customer loyalty” in the international market. In accordance with our cultureâ € œIWe comply with the principle to ensure efficiency from top to bottom: “Today must be done today. It speeds up the time of your final product entry. “As a factory driven by customers, your satisfaction is the best priority. If you are interested in our heavy copper PCB, please contact us via our contact link here.

Is PCB China Heavy Copper?

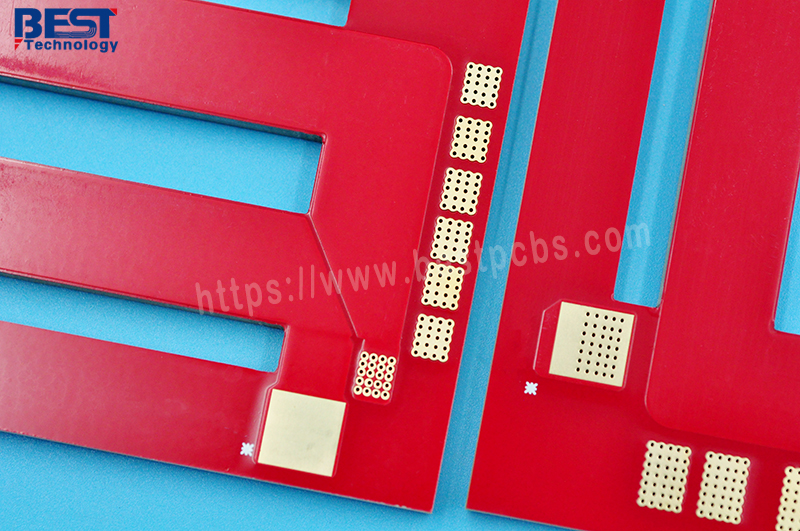

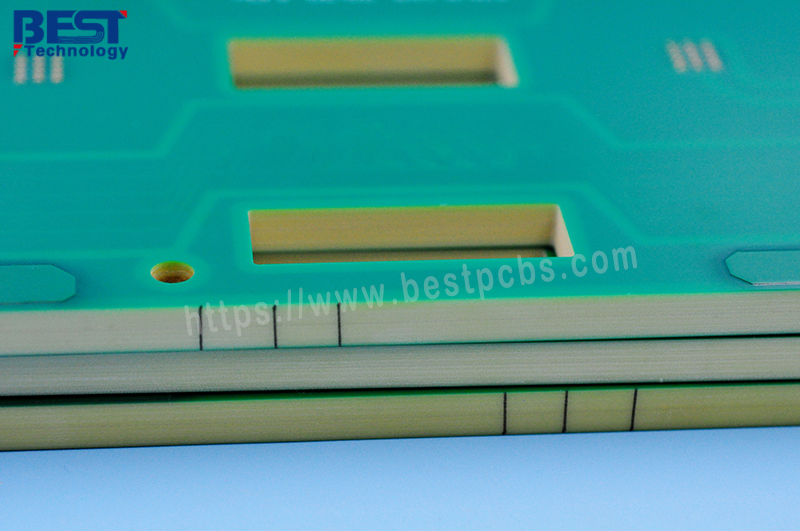

Heavy copper PCB is built with a coat of copper that is thicker than a standard 1oz. These boards often carry the thickness of 2 oz to 6oz copper, but they can go beyond it depending on the application. When made in China, this council benefit from production that can be discharged and cost -effective services. Increased copper allows better current flow, increase in thermal performance, and stronger physical integrity.

What is the manufacturing process for China Heavy Copper PCB 4Layer?

Producing Aâ China Heavy Copper PCB 4Layer ‘requires precision. Each layer starts with high quality basic ingredients. Then copper is laminated and carved carefully. The coating is reinforced with an optimized electroplating formula. The multi-laying bond process uses lamination step by step to prevent the resin cavity. Special drilling equipment and strict process control Avoiding disappointment and grinding. Every step is monitored to avoid surface roughness and shift in the inner layer.

What are the advantages of China’s heavy copper PCB?

Its benefits exceed durability. Here are the main advantages:

- Handling Current:Increased copper means a better current carrier capacity.

- Thermal Control:Heat spreads faster, protecting the main components.

- Mechanical strength:The board holds the vibration and mechanical pressure.

- Multilayer Support:Complex layouts become easily managed.

- Long live:Longer boards, even in difficult environments.

What applications for heavy copper PCB?

Heavy copper PCBs are used in industries that require strength and stability:

- Power Electronics:Used in solar inverters, UPS, and charging stations.

- Industrial Control:Equipment, sensors, robotics, and automation equipment.

- Aerospace:Suitable for high reliability aircraft systems.

- Automotive:Key for EV battery management and control system.

- Medical:Critical for stable reading in pH meters, ECG devices, and more.

Chinese Copper PCB manufacturer

Many Chinese PCB manufacturers are now specializing in heavy copper PCB production. However, not all meet tolerance, flatness, and strict standards are needed. General complaints include council warping, poor resin problems, and copper filling holes. The reliable heavy copper PCB manufacturer in China uses a time-monitoring system, better resin control, and balanced copper distribution in all layers. Below are three trusted producers in China, known as their strong track record in this field.

1. The best technology

The best technology is prominent because of his expertise in producing multilayer heavy copper PCB with copper thickness up to 10oz. What distinguishes them is the laminate technique of their steps, which helps manage uneven copper areas and reduce surface warping during SMT. With the support of DFM in-house and a smart mes tracking system, Best also provides a fast prototype ‘important advantage in a sensitive project. We are certified for ISO 9001, IIatf 16949, AS9100D, and ISO 13485, which includes industries from automotive to aerospace and medical.

2. Syringe technology

Injecting is one of the large -scale PCB manufacturers of China, offering sophisticated capabilities in the production of high -power circuit boards. They have strong equipment for thick copper etching and are known for a strict quality examination at each stage of production. Their automatic production pathway reduces manual errors, helping to ensure consistent circles and coating of copper, especially in 4â € “6 layer designs used in electrical electronics.

3. Wus Printed Circuit Co., Ltd.

WUS is a long -standing Chinese PCB maker who supplying industrial and automotive customers around the world. They have a deep technical experience in the thermal management PCB and offers a solid process control for the manufacture of heavy copper. Their ability to handle complex multilayer piles and consistency in the thickness of copper coating makes it a reliable choice for high reliability applications.

In short, the demand for the production of Chinese heavy copper PCB is increasing, but so is the challenges, especially in the distribution of heat, reliability of coating, and delivery time. Working with proven producers like the best technology, injections, and WU gives confidence that the principles that make Prototi will meet the principles that are fast and advanced.

How do heavy copper PCB manufacturers ensure fast prototypes?

Fast shipping problem. Advanced Chinese factory overcoming this challenge with:

- DFM Collaboration:The design is reviewed earlier to avoid delays.

- In-house process:From lamination to final testing, everything is under one roof.

- Material reserves:Copper storage and strategic resin avoid deficiencies.

These steps help reduce completion time while increasing consistency.

Why Choose the Best Technology for Chinese Copper PCB?

Many clients choose the best technology for heavy copper PCB solutions’ and for good reasons. This is why:

- Manufacturing beliefs:Control Control Advanced avoiding poor copper in the hole wall and ensures a stable conductivity.

- Surface Feracy:Even when the thickness of copper varies, the lamination process of step by step they keep the board flat for SMT.

- Warpage Prevention:Optimized resin ratio and laminated method reduces PCB deformation during solder.

- Speed:DFM in-house experts and intelligent mes systems help shorten the sampling cycle.

- Quality Commitment:All boards passed the AOI, X-ray, and ending electricity tests.

- Certification:ISO9001, IATF16949, ISO13485, and AS9100D showed our industrial expertise.

In addition, the best technology maintains flexible supply chains and price control through long -term supplier partnership. With the growth of copper prices and customer urgency, it is a large plus.

In short, along with high power electronic needs and high reliability power, China the weight of the PCB PCB manufacturer is increasing to meet demand. But high copper content carries challenges such as thermal imbalances, high copper gaps, and the risk of coating. The best technology offers targeted solutions through proven processes, professional DFM support, and stable supply chains. We are the original producer of China Heavy Copper PCB for fast prototypes. We have our production route. Our team helps change the design into a product “fast and reliable. That is what Edge buyers are looking for today. If there are demands for heavy copper PCBs related to or want to visit our factory, a warm welcome for contact” WeA throughEmail at [email protected]Or by calling us +86-755-2909-1601.

Tags: China Heavy Copper PCB, China Heavy Copper PCB for Prototype Prompt

This entry was posted on Thursday, June 26, 2025 at 17:35 and submitted under the best PCB, BestTPCB. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-06-30 01:05:21.