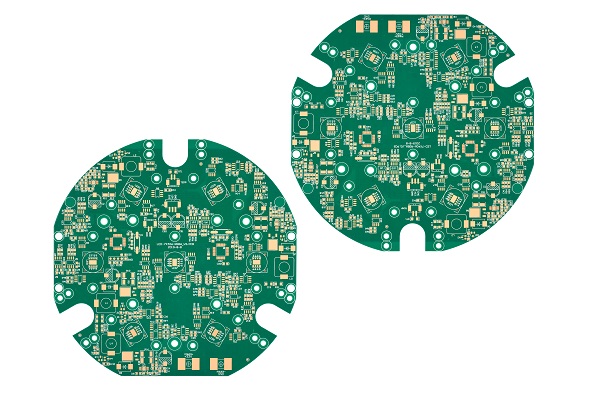

What is the LED UV circuit board?

The UV LED circuit board is a special engineering circuit board that is designed to be installed, power, and diodes of cool ultraviolet light transmitters (LED UV). Unlike visible light LEDs, LED UV emits light in the ultraviolet spectrum, usually between 200nm and 400nm, and is divided into:

- UV-A (315â € “400nm)-used in curing, fluorescence, troop detection.

- UV-B (280 € “315NM)-used in medical therapy and photobiology.

- UV-C (200 € “280nm)-used in sterilization and germ applications.

PCB acts as:

- Electric Pathway – provide a stable current for each UV LED.

- Mechanical Support – Maintaining the LED that is installed and aligned safely.

- Heat Disipation Platform – Managing the excess heat produced by UV LEDs during surgery.

Because LED UV is sensitive to heat fluctuations and at this time, the choice of PCB material and design directly affects the performance, age, and efficiency of light output.

Why choose a copper PCB for LED UV?

Copper PCB for LED UV is considered a premium option for high and long UV LED applications. Compared to aluminum or standard FR4, copper offers a very high thermal conductivity ‘up to 400 W/Mâ · K, almost double the aluminum and superior electrical conductivity.

Main Advantages:

- Superior thermal management

UV LEDs produce more heat per watt than standard LEDs. Excessive heat shorten age, causing deviations of wavelengths, and reducing light efficiency. Copper PCB moves heat more efficiently to the heat sink or cooling system, making sure the LED operates in a safe temperature range.

- Better electrical conductivity

Low electrical endurance from copper means minimal power loss, consistent brightness, and stable performance on all LEDs on the board.

- Higher current capacity

Copper can carry a higher current without overheating, allowing a higher density LED array for strong UV output.

- Endurance in a hard condition

UV applications often involve high intensity, heat, and sometimes chemical exposure. Mechanical and chemical stability of copper makes it more reliable than aluminum in such conditions.

- Etching precision circuit

Copper allows for smoother traces, tighter distances, and complex multi-layer designs, ideal for a concise high-power UV LED module.

Main design considerations for adjusted UV LED PCB

When designing a special UV LED circuit board, engineers must carefully overcome several important factors:

1. Thermal management strategies

- Use a heavy copper layer (2oz to 6oz) for better heat spread.

- The thermal Vias integration to move heat from the LED pads to the back side for dissipation.

- Use copper PCBs or hybrid construction with metal heat spreaders for extreme cases.

2. Election of Copper Thickness

- Low UV LED: 1oz copper may be enough.

- High power LED UV: 2oz to 6oz copper layers recommended for optimal heat conduction.

3. UV resistant material

- Use a solder mask that holds yellowish, cracks, or degradation from UV exposure.

- Avoid plastic or laminated damaged under UV rays.

4. Optimizing the layout of the circuit

- Even the LED distance for uniform light output.

- Minimize the length of the trail between LEDs to reduce resistive loss.

- Isolated power zone for multi-length UV LEDs.

5. Surface final selection

- Enig (Electric Nickel Soaking Gold): Corrosion resistant and suitable for fine pitch LEDs.

- Silver Immersion: excellent conductivity and thermal transfer.

- Avoid the final results that are vulnerable to oxidation under UV exposure.

6. Integration of Hot Sink

- Make sure the PCB design matches the mechanical interface for active or passive cooling solutions.

- For high output UV modules, forced cooling or liquid cooling may be needed.

Typical Application of PCB Copper Led UV

Because of the durability and capability of heat handling, copper PCB for UV LEDs is used in:

- UV curing system

- Sterilization of water, air, and surface

- Medical Equipment & Tooth

- Detection & Fake Security

- Photolithography & PCB Fabrication

- Industrial Printing & Coating System

Copper PCB vs. Aluminum pcb for LED UV

| Feature | Copper pcb for led uv | Aluminum pcb for UV LED |

| Thermal conductivity | ~ 400 W/Mâ · K | ~ 200 w/mâ · k |

| Electrical conductivity | Very good (low resistance) | Currently |

| Current capacity | High (supporting high -power LEDs) | Currently |

| Durability | Extraordinary (heat & chemical resistance) | Good |

| Cost | Higher | Lower |

| Ideal use | High-power UV, high density, long-layspan | UV medium-power, friendly-friendly |

Summary: If you need maximum efficiency, age, and performance, especially in high intensity UV applications’ Copper PCB is a clear winner despite higher costs.

Why partner with the best technology for your adjusted UV LED PCB?

The best technology has more than a decade of expertise in designing and producing special UV LED circuit boards and copper PCB for UV LED applications.

Our advantage:

- Custom technical support – from schematic design to thermal simulation.

- High-capacity manufacturing-heavy copper up to 10oz, a single or multi-layered design.

- Material Expertise in Lamination and UV-Stabil Solder Mask and Mask.

- Strict quality standards – IPC compliance class 2/3, 100% electricity and thermal testing.

- Fast Prototype – Quick turnover from design to shipping.

We ensure that each PCB is optimized for thermal stability, optical efficiency, and long -term reliability in the demanding UV environment. If you want to know more about copper PCB or Aluminum PCB, welcome to contact us at [email protected].

FAQ

T1: Can PCB copper handle high power LEDs?

Yes. High thermal conductivity of copper ensures that heat is quickly removed from the LED intersection, prevent overheating and extend life.

T2: What is the thickness of copper recommended for UV LED boards?

2oz to 6oz copper is ideal for high -power LED UV. Low power design can use 1oz copper.

T3: Is copper PCB always better than aluminum for LED UV?

For high -performance applications, long life, and high power, copper is superior. Aluminum can be accepted for budget -conscious design, medium power.

T4: Can PCB LED UV be adjusted in shape and size?

Yes. We offer full customization in dimensions, cluties, LED settings, and connector placement.

T5: How does UV light affect PCB material?

Prolonged exposure to UV can reduce some soldier masks, plastic, and adhesive. We use UV resistant materials to ensure long -term durability.

Tag: Copper PCB for UV LED, UV LED circuit board

This entry was posted on Friday, August 8, 2025 at 18:05 and submitted under the best PCB, BestTPCB, MCPCB, Metal Core PCB. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime