When you see a smartphone, a car navigation screen, or even a medical monitor, you see through the TFT screen. TFT, which stands for Thin Film Transistor, is a technology that allows the control of millions of pixels, producing sharp images and bright colors. However, behind the glass layer of the display lies something as important – PCB TFT.

TFT PCB is a print circuit board that supports and controls the TFT display module. Without it, the panel is only passive glass, cannot turn on or show pictures. PCB provides “intelligence” that makes the appearance alive. It manages signals, regulates strength, moves the back lights, and often integrate the touch interface.

Understanding how PCB TFT functions are very important not only for engineers but also for product developers, purchasing managers, and anyone who works with a display module. Let’s explore what TFT PCB is, how it works, where it is used, and why choosing the right manufacturing partner is very important.

What is TFT PCB on a screen?

In essence, TFT PCB is an electronic backbone of the TFT screen module. TFT display consists of two main parts:

- TFT Glass – It contains a thin film transistor that controls liquid crystal molecules, determining how light passes through each pixel.

- PCB TFT – It supports TFT glass by supplying power, processing signals, and controlling back lights.

Think about TFT glass as a screen canvas, and TFT PCB as a control center. Glass defines resolution, pixel density, and visual quality, but without PCB, there is no way to convert system signals into images.

For example, the 7 -inch automotive TFT screen may have a resolution of 1024 × 600. TFT glass determines the number of pixels, but the PCB that pushes each pixel according to the instructions of the car mainboard.

How does PCB TFT work?

TFT PCB functions like a translator between the system and appearance. The task can be divided into three main functions:

1. Signal processing

Host devices – Whether smartphones, industrial controllers, or infotainment systems – enter digital image data. But this data needs to be formatted into instructions that control each pixel.

- Signal input: General formats include LVD, EDP, or MIPI DSI.

- ICS Driver: This chip on the PCB deals the signal and decides how each pixel must behave.

- Line and column control: signal distributed row by row and column by column, activating specific transistors on TFT glass.

For example, when displaying a red point in the smartphone screen corner, ICS PCB Driver counts which pixels will provide energy and how to modulate them to show red.

2. Power management and background

TFT display requires some power rails: one for logic, one for glass, and one for LED background lights.

- Voltage regulation: PCB includes regulators to maintain a stable voltage, usually starting from 1.8V for logic up to 12V for back lights.

- Backlight Control: LED Driver adjusts brightness through PWM (Modulation of Pulses Width) or current control. This makes it possible to dim the screen for night use or increase brightness for outdoor visibility.

Without this circuit, the screen will blink, show unstable images, or fail to reach uniform brightness.

3. Integration of touch controller

In many TFT modules, PCB also supports the touch layer.

- Capacitive touch control: Sense change in capacitance when the finger touches the screen.

- Resistive touch control: detection of pressure applied to the surface.

PCB processes this touch signal and communicates it back to the main system.

This is how to rub your smartphone screen or tap the medical device control panel translated into action.

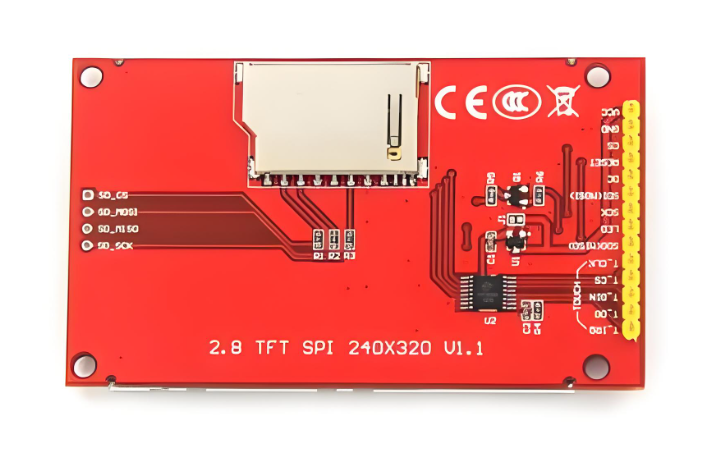

What are the main components on TFT PCB?

Although the PCB looks small, it is packed with vital parts. Let’s look in detail:

- ICS Driver: Often fine pitch chips that directly control rows and pixel columns. They are very important for the sharpness of the image and color accuracy.

- ICS Power: Conversion of input power into different voltage levels required by the appearance and touch controller.

- Backlight Circuit: Including LED drivers, current regulators, and protection circuits.

- Touch Controller: Only on the screen that supports touch. Handling finger tracking, multi-touching, and introduction of movement.

- Connectors and FPCs: provide bridges between PCB and host systems. For slim devices, flexible print cables (FPC) are widely used.

- The oscillator and circuit Time Settings: Make sure that the signal reaches the glass with a perfect synchronization.

In automotive or upper medical display, additional components can be added, such as temperature sensors, EMI filters, and excessive power circuits for safety.

What is the TFT PCB application?

TFT PCB is used in almost every industry where visual information is needed. Some of the most common applications include:

- Consumer Electronics – Smartphones, Tablets, Laptops, TVs.

- Automotive – Digital dashboard, navigation system, entertainment screen.

- Control industrial equipment, Human Machine Interface (HMIS).

- Medical devices – Patient monitor, diagnostic equipment.

- Aerospace and defense – coarse display with high visibility and endurance.

In each application, PCB is adjusted to meet specific requirements, whether it is compact, heat resistance, or EMI protector.

What are the design considerations for TFT PCB?

Designing TFT PCB is more challenging than many other types of PCB due to high -speed signals, compact layouts, and strict reliability needs.

1. High -speed signal integrity

TFT PCB often carries LVD, MIPI DSI, or EDP signals that run in hundreds of Mahehertz.

- Impedance control: Differential trail is diverted with controlled impedance, usually 90 Ω ± 10%.

- Long matching: Pair signal is suitable for avoiding slope.

- Foundation and Shield: Reference aircraft are planned carefully to minimize crosstalk.

2. Power distribution and stability

- Double rails: A single TFT PCB may require 1.8V, 3.3V, 5V, and 12V simultaneously.

- Filtering: LC filters fine power for sensitive circuits.

- Decoupling capacitor: placed close to IC to reduce noise and voltage dips.

3. Thermal management

- BACKLIGHT HEAT: The LED backlight produces heat. Pour copper, thermal Vias, and sometimes aluminum-supported designs are used.

- IC heat dissipation: High power driver IC may require thermal pads to spread heat on the PCB.

4. Constraints of mechanical factors and shapes

- Thickness: Many mobile devices require ultra-tiped PCB (as low as 0.4 mm).

- Flexibility: For devices that can be folded, PCB must bear recurring bending.

- Installation hole: placed carefully to avoid pressure on the glass.

5. Reliability for a hard environment

- Automotive: area area (-40 ° C to 125 ° C), vibration resistant design.

- Medical: Compliance with strict safety standards, including isolation for devices that are connected with patients.

- Aerospace: Light board but very reliable, often uses sophisticated laminate.

6. Cost vs. Performance

Each design option affects costs.

- More layers = better performance, higher costs.

- Enig is complete = better for fine pitch, but more expensive than OSP.

- Rigu-flex hybrid PCB = Save space, but increases production difficulties.

Example: Simple home appliances TFT PCB can use 2-Lapis OSP finish boards. TFT PCB Automotive Infotainment may require 8 layers with an excessive finish enig and power circuit.

How is PCB TFT produced?

PCB TFT production combines standard PCB processes with advanced assembly techniques:

1. Material selection: FR4 is the most common for rigid PCB, while polyimide is used for flexible TFT modules.

2. Coper and copper etching: Some copper layers are stacked and engraved to make signal and power traces.

3. Mount Mount Surface: Components such as ICS Drivers and regulators are installed using an automatic SMT machine.

4. Solder fine-Pitch: Because the display connector and IC have very small cushions, solder precision is needed.

5. Testing: Including electrical continuity, signal quality, and checking backlight performance.

6. Validation of reliability: For critical industries, additional tests such as thermal cycles, humidity resistance, and vibrations are carried out.

The end result is a strong PCB that works smoothly with TFT glass, provides functionality and endurance.

What is the difference between TFT PCB and other PCB?

Different display technology requires different PCB support.

- TFT PCB vs OLED PCB: OLED is its own illumination, so that their PCB mainly manages signals and power, while TFT PCB must also handle back lights circuits.

- TFT PCB vs LED Display PCB: LED Display PCB directly controls thousands of LEDs in the panel, often for outdoor use or large format. TFT PCB is designed for a compact glass -based display.

- Cost Comparison: PCB TFT is usually cheaper than PCB OLED, making it a cost -effective choice for many industries.

This is why TFT remains popular: this provides a balance between performance, costs, and maturity of technology.

Why choose the best technology for making TFT PCB?

As one of the best PCB manufacturers in China, our goal is to give our customers with the best quality products and services at the most competitive prices, and to become a reliable long -term partner of our customers in the making and assembly of PCB.

Since it was founded in 2006 as a printed circuit board manufacturer, the best technology has focused on high -quality, low to medium quality PCB fabrication, PCB assembly and electronic manufacturing. Our products and services include 1-100 print circuit board layers, thru-hole assembly, SMT assembly including BGA assembly, component sources, Turnkey box making and electronic product development. From consumer electronics to the appearance of sophisticated space, the best technology has the ability and expertise to support projects from any scale.

FAQ

1. What materials are used in TFT PCB?

Most TFT PCBs use FR4 for rigid and polymide parts for flexible cables. Sophisticated material can be used in high frequency or high reliability design.

2. Can TFT PCB support the touch screen function?

Yes. Capacitive or resistive touch control is often integrated into a PCB to handle user interactions.

3. How thin PCB TFT?

Flexible TFT PCB can be as thin as 0.15 mm, while rigid design is usually 0.6-1.6 mm.

4. Are TFT PCBs different for automotive appearance?

Yes. Automotive TFT PCB is designed for durability, with heat -resistant material, vibration tolerance, and broader operating temperature range.

5. How much is the typical TFT PCB?

Costs vary based on size, number of layers, and applications. PCB TFT consumers are usually low in cost, while automotive boards and medical levels are more expensive because of higher standards.

Tag: TFT PCB

This entry was posted on Saturday, August 30, 2025 at 9:55 am and was submitted under the best PCB, BestTPCB, FAQ, FR4 PCB. You can follow any response to this entry through RSS 2.0 bait. You can jump to the end and leave a response. Pinging is currently not permitted.

News

Berita

News Flash

Blog

Technology

Sports

Sport

Football

Tips

Finance

Berita Terkini

Berita Terbaru

Berita Kekinian

News

Berita Terkini

Olahraga

Pasang Internet Myrepublic

Jasa Import China

Jasa Import Door to Door

Originally posted 2025-09-01 03:42:50.