Aluminum -based PCB is a strong choice for modern electronics, especially where it is important hot control. Whether you design LED lights, power supplies, or automotive electronics, aluminum PCBs help you manage temperatures, protect components, and provide stable performance. Compared to standard boards, they offer better heat dissipation, which can make a big difference in product reliability.

In the best technology, we produce high -quality aluminum PCBs using certified materials and advanced processes. With certification like ISO9001, ISO13485 for medical devices, IAF16949 For automotive approval, and UL, we provide reliable circuit boards that are tailored to your needs.

Aluminum -based PCB manufacturer

What is Aluminum PCB?

Aluminum PCB-also called Metal Core PCB (MCPCB)-is a type of printed circuit board that uses aluminum as a basic ingredient instead of common fiberglass material (FR-4). The council consists of three main layers:

- Aluminum base layer for strength and heat conduction

- Isolation of dielectric layers to separate metals from copper

- Copper circuit layer for electricity connection

This structure helps attract heat from components that are sensitive to heat such as LEDs, transistors, or electric devices. Simply put, aluminum PCB helps keep things cold, especially in high-empowered applications or high temperatures.

What are the pros and cons aluminum PCB?

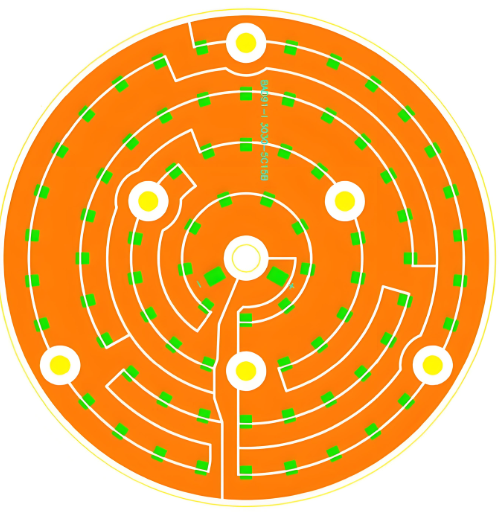

Aluminum -based PCB is made from aluminum aluminum aluminum aluminum plates is low (the structure shown in the figure below). This board offers excellent thermal conductivity, electrical insulation, and engine capability. Compared to traditional FR-4 boards, aluminum PCBs with the same thickness and width of traces can carry higher currents. They also have the power of dielectric damage up to 4500V and thermal conductivity is greater than 2.0 W/Mâ · K. In the PCB industry, aluminum -based boards are the most widely used metal core PCB. The main advantages include:

- Support for Mount Surface Technology (SMT)

- Thermal diffusion is very efficient in the circuit design

- Lower operating temperatures, higher power density, high reliability, and longer product age

- Smaller product sizes, reduce hardware and assembly costs

- Replacement for fragile ceramic substrates, offering better mechanical durability

But they also have some limitations:

- Lower flexibility: Aluminum boards cannot be bent like a flexible PCB.

- More complex manufacturers: special processes are needed to drill and metal -based etc.

- Limited layer: There is a multi-layer aluminum PCB, but more difficult and more expensive to produce.

Most technology, we help customers balance these factors. Our technical team guides you through the design and selection of materials to ensure your PCB aluminum functions well for your application.

Aluminum pcb material property

Aluminum -based PCBs are usually made of aluminum alloys such as 5052, 6061, or 3003. These materials are chosen to deal with heat well, maintain electrical insulation, and provide mechanical support. Some customers may be confused about them and the difference between this material. Here the best technology that includes property of each material, hopefully this can help you choose which is the best for your project.

| Owned by | 5052 aluminum | 6061 Aluminum | 3003 Aluminum |

| Composition | Al-Mg alloy | Al-Mg-si | Al-Mn blend |

| Thermal conductivity | ~ 138 W/Mâ · K | ~ 167 W/Mâ · K | ~ 160 W/Mâ · K |

| Electrical conductivity | ~ 35% IAC | ~ 40% IAC | ~ 40% IAC |

| Tensile strength | 210â € “230 MPA | 260â € “310 MPa | 130â € “180 MPa |

| The power of melting | ~ 130 MPa | ~ 240 MPa | ~ 115 MPa |

| Elongation | ~ 12â € “20% | ~ 8â € “10% | ~ 10â € “20% |

| Corrosion resistance | Very good | Good | Very good |

| Form capability | Very good | Good | Very good |

| Engine capability | Fair | Good | Fair |

| Cost | Currently | Higher | Lower |

| General use on pcb | LED lighting, power electronics | High power structural application | Consumer electronics, general use |

Quick Note:

- 5052 is preferred for excellent corrosion resistance and good thermal performance, often used in PCB of external lighting or sea applications.

- 6061 offers better strength and engine capabilities, suitable for PCBs that demand mechanically or large size boards.

- 3003 cost -effective with good thermal resistance and corrosion, ideal for low to moderate power electronic boards.

How thick is aluminum pcb?

Aluminum PCB varies in thickness based on design and application needs. General thickness ranges from 0.8mm to 3.2mm, but special options are available. Here are the Rules of Standard Aluminum PCB thickness:

- Single layer board: usually ranges from 0.2mm to 0.5mm, suitable for simple circuit design.

- Multiple layer board: generally 0.5mm to 1.2mm, balance both signal transmissions and heat dissipation needs.

- Multi-layer board: thickness starts from 1.2mm and can reach up to 10mm, ideal for high-power electronic devices.

For applications with high thermal conductivity requirements (such as LED lighting and power electronics), aluminum PCBs can use thinner copper foil (ranging from 35îief to 280îief In such cases, the thickness of the minimum board can be as low as 0.075mm.

Most technology, we help customers choose the right thickness based on the current flow, heat output, and mechanical strength. Thicker boards may be more expensive but offer better performance in demanding arrangements.

What is the maximum temperature for aluminum PCB?

Aluminum PCB is built for high temperature conditions. The dielectric layer determines the maximum working temperature, which usually ranges between 130 ° C to 150 ° C.. Special materials can be higher, depending on the design.

Why is this important? In LED lighting or automotive power module, excess heat can damage the components. By using an aluminum PCB, you keep the temperature down and extend the life of your product. If you want to be used in extreme high temperature applications, we have a ceramic PCB that can reach 850 ° C.

The process of making aluminum pcb – simplified

1. Material preparation: Select the right aluminum base, apply dielectric material, and add copper foil.

2. Drilling: CNC machines make holes for VIAS and component placement.

3. Circuit imagery: Forestry is applied, and UV lamps are used to determine the circuit pattern.

4. ETSA: Unwanted copper is removed, leaving only the desired circuit.

5. Plating: Coating through a hole can be used if needed for connection.

6. Solder Mask Application: The protective layer prevents oxidation and bridges solder.

7. Completed Surface: Common final results include ENIG (Electric Nickel Soaking Gold), HASL (Hot Air Solder Leveling), or OSP (Organic Soldaability Preservative).

8. Testing: Electricity and Thermal tests ensure that each board performs as needed.

Below is the process of making detailed aluminum -based PCBs. The best technology uses a sophisticated mes system for full quality and strict quality control. We support the prototype and mass production with fast turnaround time.

How is the cost of aluminum -based PCB?

Several factors affect the cost of aluminum PCB:

- Material level: aluminum and higher quality thermal materials are more expensive.

- Size and complexity of boards: larger boards or complicated design prices.

- Copper thickness: thicker copper adds material costs and processing.

- Surface Finish: Enig is more expensive than hasl or OSP.

- Quantity: Lower output output orders per unit.

In general, the aluminum PCB costs more than FR-4 for simple design but offers cost savings in thermal management. For example, using an aluminum board can eliminate the need for additional heat sinks or cooling fans. Most technology, we offer competitive prices and help you optimize designs for costs and performance.

What is the difference between aluminum PCB and FR-4?

The main difference between the aluminum PCB and the FR-4 PCB lies in the basic material and how each board handles heat and mechanical stress.

Aluminum PCB uses a metal base (usually aluminum) which helps do heat from components. This makes them a good choice for high power circuits such as LEDs and power supplies. Conversely, PCB FR-4 is made of fiberglass. They are versatile and cost effective but have poor thermal conductivity, which can be a problem in sensitive designs. Here a brief comparison side by side:

| Feature | Aluminum PCB | FR-4 PCB |

| Basic material | Aluminum (metal nucleus) | Fiberglass (FR-4) |

| Thermal conductivity | Height (1,0â € “3.0 W/Mâ · K) | Low (~ 0.3 W/Mâ · K) |

| Heat dissipation | Very good | Limited |

| Strength | Strong and durable | Currently |

| Flexibility | Low (rigid) | Higher (can be rigid or flexible) |

| Cost | Slightly higher (for material) | Lower for basic design |

| Typical use | LED, Electronic Power, Automotive | Consumer electronics, general use |

Use an aluminum PCB when your design needs to handle heat efficiently and survive from a difficult environment. Use FR-4 when the thermal demands are low, or you need a flexible or multi-layer board.

When to use an aluminum PCB?

Aluminum PCB is the right choice when you need:

- Efficient heat dissipation

- Reliable performance in high power applications

- SAVE DESIGN SPACE WITHOUT ADDITIONAL HEAT SYKN

General applications include:

- LED lighting system (for example, street lights, automotive lights)

- Power Converters and Inverters

- Battery charger

- Audio amplifier

- Telecommunications and Pangkalan Station

If your design is struggling with overheating or if your product needs to run 24/7 without failure, aluminum PCB can help you achieve it.

In the best technology, we specialize in special aluminum PCBs with strict quality standards and professional support. Whether you need a single layer board, multi-layer, or special-shaped board, we have made you closed. Ready to explore the aluminum PCB solution? Contact the best technology today for technical offers or consultations.

FAQ

1. Can PCB aluminum be used in flexible applications?

No, aluminum PCB is rigid. If you need flexibility, consider a flexible PCB or hybrid design.

2. Is the aluminum PCB more expensive than FR-4?

Yes, but they reduce the need for additional cooling, saving costs in the long run.

3. Can I use an aluminum PCB for RF applications?

Yes, with the right dielectric material, aluminum PCB can work on the RF circuit.

4. How fast can I get an aluminum PCB from the best technology?

We offer a fast waiting time, depending on the design and quantity. Contact us for the details.

5. Do you give a sample for testing?

Yes, we support prototype orders to help you test and complete your design.

Tags: aluminum -based PCB, aluminum -based PCB costs, aluminum PCB vs. FR4

This entry was posted on Wednesday, July 30, 2025 at 17:25 and submitted under the best PCB, BestTPCB, FAQ, MCPCB, Metal Core PCB. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime