Have you ever wondered why some electronic devices failed even when PCB looked perfect? Or why does high volume production sometimes provide inconsistent boards? These problems often track back to component defects that are not detected, poor solder, or wrong connection. Without proper testing, even a single defective part can cause product failure, expensive withdrawals, or customer dissatisfaction.

This is where ICT test equipment enters. By testing in-circuit (ICT), producers can quickly detect lost components, shorts, open, and wrong placement before the board leaves the production path. With the right electronic test and in-circuit test equipment, you get a fast, accurate, and reliable PCB validation from each PCB, saving time and money.

In this article, we will answer key questions such as:

- What exactly is ICT examiner, and how does it work?

- Why is ICT testing so important for electronic manufacturing?

- What is the difference between ICT from functional testing or flight probe testing?

- When should you use TIK functional testing versus for your board?

By understanding these points, you will see how ICT tests can prevent defects, increase production efficiency, and ensure reliable final products—The potential headache potential is a controlled and predictable result.

What is a ICT examiner?

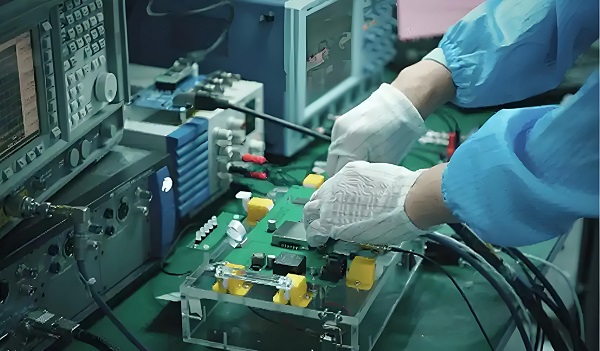

ICT examiner is a system designed to test in-circuit (ICT) on the printed circuit board after assembly. This is often recognized by “bed” equipment, which has hundreds or even thousands of pins arranged to contact certain points on the PCB. Each PIN is in accordance with the PAD, through, or the test point, allows the tester to measure voltage, resistance, and current at the component level.

ICT examiners can:

- Detect lost, wrong, or wrong components.

- Identification of open circuits, short circuits, and solder defects.

- Measure parameters such as resistance, capacitance, and diode orientation.

- Verification of integrated circuit placement and connectivity.

Because ICT is comprehensive and fast, it has become an industrial standard approach, especially in high volume production paths.

Why is the ICT test important?

ICT test is important for several reasons. In large -scale manufacturing, even one defect can rustle into thousands of damaged units. Detect initial problems reduce costs, avoid withdrawal, and protect brand reputation.

For example, in automotive electronics, where the safety system depends on the perfect PCB, ICT is very important. Errors that are not detected in the airbag control system can have serious consequences. In consumer electronics, ICT prevents the wrong smartphone, laptops, or household appliances from reaching the market.

ICT test is also important for improving the process. This gives statistical data engineers that highlight repeated problems, such as bridging polishing or wrong component placement. Producers can use this data to improve the process, reduce the rate of defects, and increase results.

What is the purpose of the ICT test?

The main purpose of ICT testing is to validate the quality and functionality of each component on the PCB. Unlike functional testing, which sees the overall behavior of the council, ICT digs details at the component level.

ICT ensures that:

- Each resistor has the correct value.

- Capacitors and inductors are present and in tolerance.

- Diode and transistor are oriented correctly.

- The integrated circuit is placed in the right and connected socket.

By capturing defects in the source, ICT reduces the risk of failure in the final stages of the product. This is very valuable in the industry where long -term reliability is very important, such as aerospace, defense, and medical devices.

How do ICT examiners work?

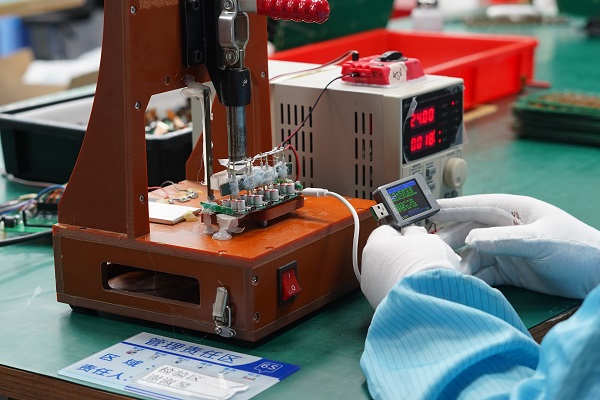

ICT examiners work by pressing in-circuit test equipment on PCB, making contact with test bearings or VIAS. After the contact is made, the system injects a signal into the board and records the response.

Here are the details of the process:

- The fixture settings are placed into a bed fixture designed for the right layout.

- Signal injection – Test probe injects electrical signals into various circuit nodes.

- Measurement – Examiners measure voltage, current, resistance, and capacitance at each point.

- Analysis – Software compares the value measured with a predetermined threshold.

- Reporting – The system highlights every failure or deviation for rapid problem solving.

ICT is very automatic, with cycle time ranging from a few seconds to less than one minute. This makes it efficient for high volume production, where time savings are directly translated to lower production costs.

ICT test advantages

- High accuracy – detect component defects that are even smooth.

- Fast cycle time – ideal for mass production.

- Detailed data – provide insight into manufacturing trends.

- Early detection – Reducing the cost of re -work and repair.

- Reliability-Improving Long-Term Product Performance.

What is the difference between functional testing and ICT testing?

Both functional testing and ICT testing play an important role in quality assurance, but they are targeting various aspects of PCB.

- ICT testing -Focus on component level verification. This checks each resistor, capacitor, diode, transistor, and IC independently. ICT identified defects such as shorts, open, wrong components, or poor solder connections.

- Functional testing – Evaluate overall system behavior. This simulates the real world operating conditions, ensuring the PCB performs the function in question. Functional testing can involve strengthening the device, running software, or checking the communication protocol.

Simply put: ICT sees how the board is built, while functional testing checks how boards behave. The two tests complement each other, and many producers use it together.

Functional testing vs ICT testing

When to use ICT and functional testing?

Choosing between ICT and functional testing depends on the project objectives and the production stage.

Use ICT testing when:

- The board is still in the manufacturing phase.

- The accuracy of the component level needs to be validated.

- High volume production requires rapid and recurrent results.

Use functional testing when:

- The assembly is almost complete.

- Product performance in real operating conditions needs to be verified.

- System level testing is needed, such as communication between several boards.

For the best results, many producers use ICT combinations and functional testing. ICT captures the initial defect, while functional testing provides final validation before shipping.

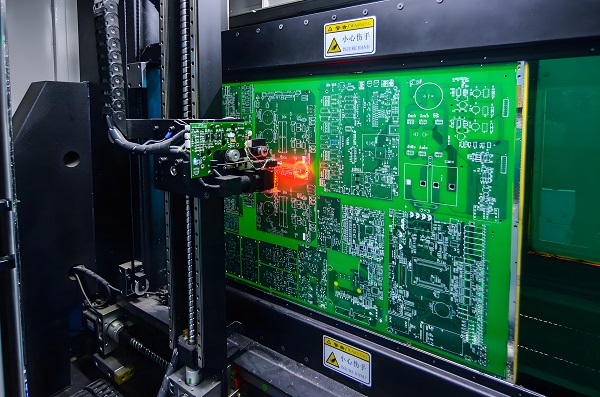

The In-Sirit vs Probe Flying Test: What is the Difference?

When comparing in-circuit (ICT) testing with flight probe testing, the difference decreases into costs, speed, and flexibility.

In-circumcision test (ICT):

- Using special in-circuit test equipment.

- Offers a fast cycle time (seconds).

- Best for high volume production.

- High -faced costs for fixture, but the cost is lower per test afterwards.

Flying Probe Test:

- Using a moving probe instead of fixture.

- Slower than ICT, because the probe moves sequentially.

- Very good for prototypes and running low volume.

- There is no fixture cost, making it more flexible and cost effective for small batch.

In practice, many producers start by testing probe flying during the prototype. After the design is complete and the volume increases, they turn to ICT testing for efficiency.

Circuit vs probe flight test

ICT testing application

ICT testing is used in various industries:

- Automotive-for critical-safety systems such as airbags, ABS, and engine control units.

- Medical devices-for life support systems, imaging equipment, and diagnostic tools.

- Aerospace and Defense-In which reliability in extreme conditions cannot be negotiated.

- Electronic Consumers – From smartphones to laptops, ensure consistent quality.

- Industrial Equipment – For automation control and power management system.

In each case, ICT contributes to higher reliability, lower failure rates, and better compliance with international standards.

Why choose the best technology for ICT and PCB testing?

The best technology is a reliable PCB manufacturer in China, trusted by more than 1,000 customers in all industries around the world. We specialize in making small to medium PCB, PCB assembly, and complete electronic manufacturing services.

As one of the most experienced circuit board suppliers, our ability includes various types of PCBs, including rigid PCBs, flexible PCBs, rigid-flex PCBs, aluminum PCBs, RF/Microwave PCBs, high-speed PCBs and high frequency, and HDI PCB. Outside manufacturing, we also provide Turnkey assembly, component sources, box assembly, PCBA testingand full electronic testing services.

With more than 19 years of experience, our technical, production and quality teams fully understand the unique needs of industry such as medical, automotive, and aerospace. We really follow international standards, working under IPC-A-600 for PCB Manufacturing and IPC-A-610 for PCB assembly. All of our products meet IPC standards for class 2, and for projects that require higher reliability, we also provide class 3 or class 3A compliance. Combined with strong technical support and competitive prices, we help customers achieve reliability and cost effectiveness.

FAQ

1. What do ICT fought for electronic testing?

ICT is an abbreviation of testing in the circuit, which validates the quality of individual PCB components.

2. Can ICT testing replace functional testing?

ICT and functional testing serve different objectives. ICT checks construction, while functional testing checks performance.

3. How long is the ICT test?

Most ICT tests only need a few seconds, depending on the number of test points.

4. Can the in-circuit test fixture be used again?

Yes, but every equipment is specifically designed for the layout of certain PCBs.

5. Which is better: tests in circuits or flying probes?

ICT is the best to run high volume because of speed. Flying probe is better for prototypes or small batch.

Tags: Electronic ICT Test, Circuit Testing, In-Sacit Test Equipment, PCB Testing

This entry was posted on Monday, August 18, 2025 at 18:37 and was submitted under the best PCB, BestTPCB, FAQ, PCB News, PCB Technology. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime