Copper pcb board Is a type of circuit board where the thin layer of copper is bound to the insulation base, usually made of fiberglass, resin, or other non-conductive materials.

What makes special copper is its extraordinary electrical conductivity, which ensures fast and stable signal transmission and efficient power delivery. Is it a single copper PCB board single sided or double copper laminated PCB circuit board, copper layer is very important for performance, reliability, and hot control.

Available in different thicknesses and configurations, copper PCB Clad boards can be adjusted to meet all demands, ranging from smartphones to medical devices.

Why is copper used on PCB?

Copper is used in a PCB for one large reason conductivity. This is one of the best electrical conductors. That means the signal can move through a fast board, with low resistance. This ensures a stable, efficient, and reliable performance on any circuit.

Another reason? Durable copper. This handles high currents without overheating. It refused corrosion. And that can be carved into a very fine line for the layout of the solid circuit. Plus, Copper Cost -Surf. Offers high performance without high prices.

In short, copper keeps the signal fast, stable power, and the cost is low. That is why it is a standard in all electronic industries.

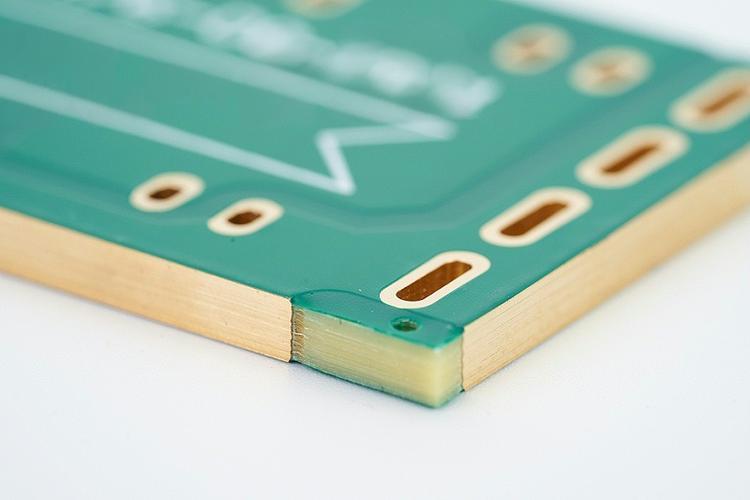

How thick 2 ounces of copper on PCB?

This refers to how much copper is scattered on one foot board.

2 oz of copper thickness is the same as about 70 microns, or 0.07mm. It might sound thin, but double the thickness of 1 oz copper, which is 35 microns. And the extra thickness brings great benefits:

- Higher current carrier capacity

- Better heat dissipation

- A stronger and more reliable circuit

Designers choose 2 OZ copper when circuits need to handle more power or operate in a difficult environment. This adds to the power without a large increase in cost or size.

What type of copper is used on PCB?

Copper used in PCB is not just any copper. This is engineered specifically for electronic manufacturing. The two most common types are:

- Electrolytic Hard Pitch Copper (ETP): This is the standard. This is more than 99% pure and offers a great conductivity and flexibility.

- Copper Annealed (RA) which is rolled up: This type is used in flexible PCB. This is softer, easier to bend, and tends to crack under repeated movements.

For rigid boards, like your remote TV or thermostat, ETP is ideal. For flexible applications, such as folded mobile phones or devices that can be used, RA copper shines.

How do I choose the thickness of PCB copper?

Choose the right one The thickness of the copper pcb board Depends on your needs. Here are some guide points:

- Current burden: More thicker copper current needs. If your board handles power, select 2 ounces or more.

- Hot Management: Thicker copper spreads hot better, reducing hotspots.

- Space Constraints: If your design is tight, thinner copper can help save space.

- Cost and weight: More copper = more weight and higher cost.

The most common thickness is 1 ounce, but 0.5 ounces and 2 ounces are also widely used. High power boards may rise to 3 ounces or more.

What is a copper PCB board?

PCB boards in copper dressed are the basic ingredients, usually FR4 (Fiberglass)Cem-1, or phenolic resin, it is laminated with a thin layer of copper on one or both sides.

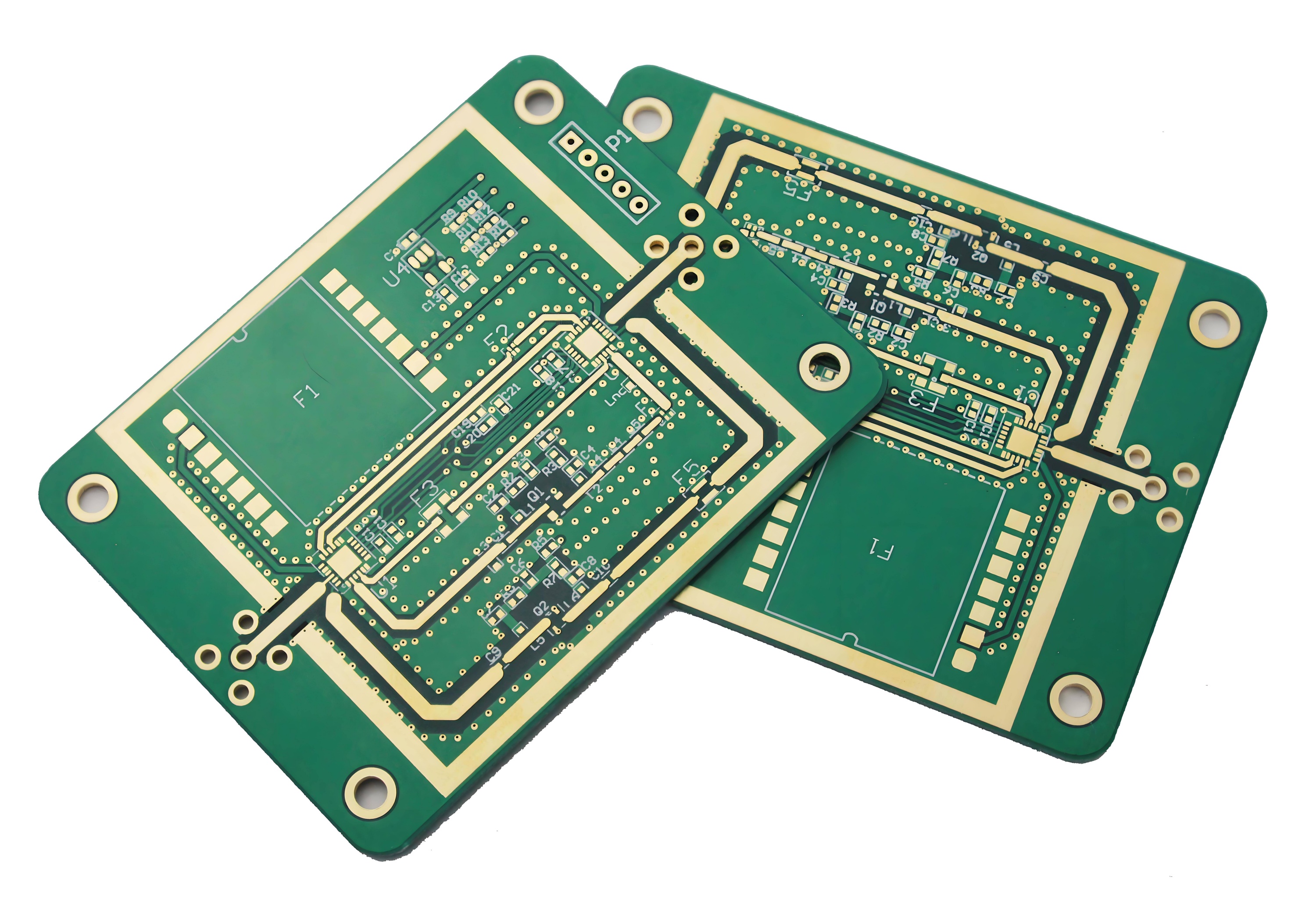

The types of copper clad boards include:

- Copper Clad Board Single Side: copper on one side

- Double Copper Clad Board: copper on both sides

- Multilayer Board: Some copper and insulation layers are stacked together

This board forms an electronic foundation. Without copper clads, there is no signal path, no connectivity, and no functionality.

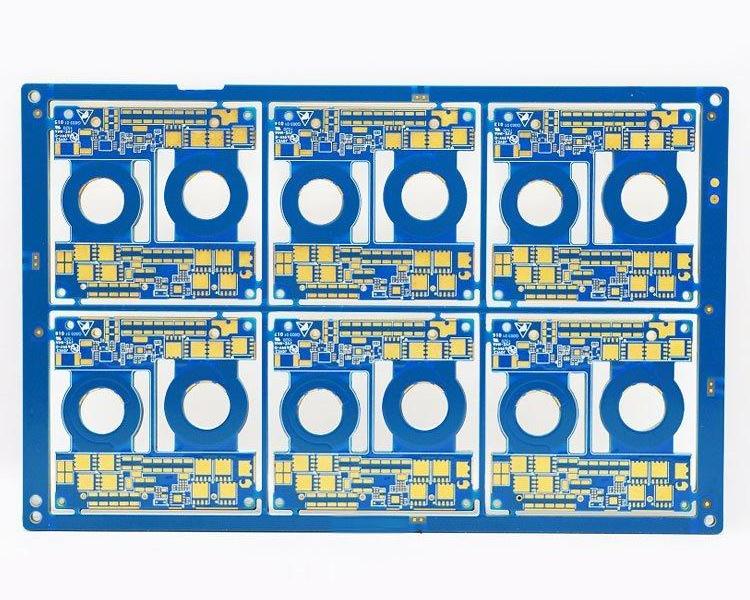

Type of copper dressed board

There are several variations, each adjusted for different needs:

- Copper pcb board one side: Good for simple and low -cost circuits. Common in calculators or basic toys.

- Double Copper PCB Board: Used in more complex electronics, offering a better stomach and signal flow.

- Copper dress laminate: This is raw material, often sold in panels, ready to be carved. Also known as an empty copper PCB board.

- Double sided copper clad laminate pcb circuit board: Offering flexibility in circuit design. General in LED lighting and power supply.

- Copper strip pcb board: Used for high current circuits. Thick copper strips are embedded to carry heavy loads.

- Copper plate laminated PCB boards: Known for high strength, used in the industrial environment.

The choice depends on the application, current needs, size, and cost.

What is the Copper Clad board used for?

Copper clad boards are used in every corner of the electronic world.

- Consumer Electronics

- Industrial control

- LED lighting

- Automotive dashboard

- Medical devices

- Communication system

Their job? To carry a signal, distribute power, and provide mechanical support. They are also important for EMI protectors, foundations, and signal integrity.

How do I remove copper from the PCB board?

There are times when making prototypes or repairs when releasing copper is needed. Here are some general methods:

- Chemical Etsa: Ferric chloride or ammonium persulfate can dissolve copper. Be careful, it is poisonous and requires the right ventilation.

- Mechanical removal: Sandaper or rotary device can physically grind copper.

- Laser removal: The upper-class laboratory uses this for ultra-president control.

Each method has a pros and cons. For fans, mechanical methods are safer. For professionals, chemicals allow mass elimination with precision.

Copper -coated PCB board vs. copper coated: what’s the difference?

Copper -coated PCB boards and copper -coated PCB boards may sound similar, but they serve different purposes.

Copper-coated PCB board means copper has been moved to certain areas’ such as holes or edges. This helps with conductivity, especially in holes through holes and multi-procedures.

Copper -coated PCB boards refer to the board where the basic material is covered uniformly with copper foil. This is usually done during the laminated stage to form a layer of initial circuit.

Short:

- Layered = targeted copper application, used to increase conductivity

- Coated = common copper layer on the surface, used to form the main circuit

Conclusion:

Copper pcb board Play an important role in modern electronics, offering excellent conductivity, thermal performance, and reliability. Whether it’s one -sided copper clad board, two -sided PCB copper board, or empty copper PCB board, each type supports the needs of different circuits.

If you are looking for a high -quality PCB Clad Clad board, reliable support, or expert suggestions, we are here to help.

Need help to choose the right copper PCB board? Reach today at [email protected]

This entry was posted on Tuesday, July 29, 2025 at 9:39 am and was submitted under the best PCB, BestTPCB, FAQ, FR4 PCB, PCB Technology. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-07-29 05:12:00.