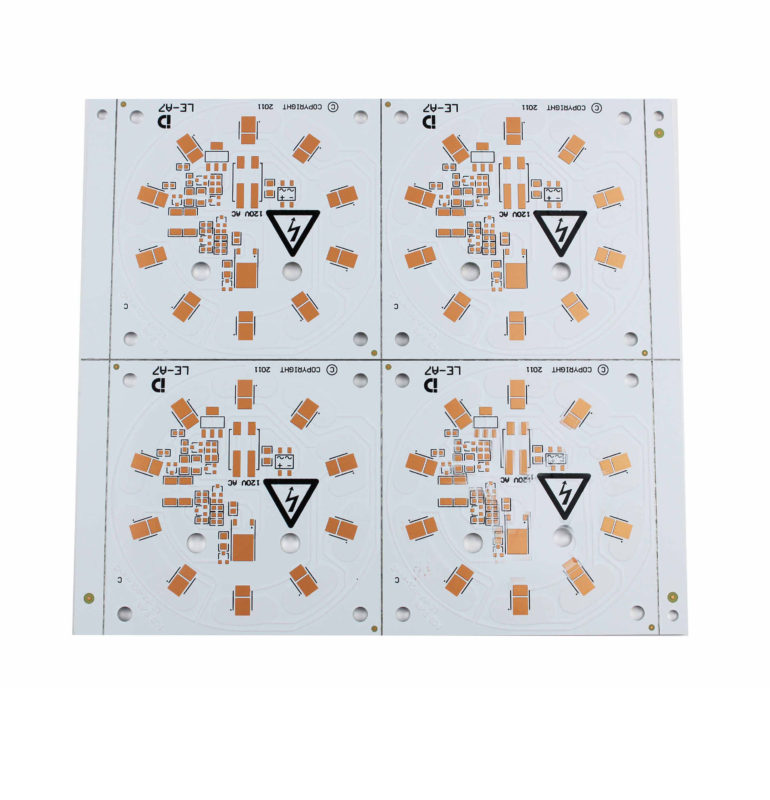

Aluminum dressed PCB is widely selected for applications that demand high thermal performance, endurance, and stable operations in difficult conditions. Whether you design an LED lighting system or power converter, aluminum PCB can offer better heat dissipation and mechanical support compared to traditional boards.

The best technology is the main custom MCPCB manufacturer in China, providing a fast aluminum PCB prototype, fabrication, and assembly service in a very large market. We have our factory in accordance with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, Reach, and Rohs. We have a competitive advantage in quality control through better manufacturing processes and through sophisticated inspection equipment. It would be nice if you can share your request for new questions with our team at [email protected]Then we can share quotes specifically.

What is an aluminum dressed in a PCB?

PCB aluminum dressed consists of a thin layer of thermal conductive dielectric material, laminated between copper circuit layers and aluminum base. This structure helps do heat from critical components. This is often used in high power applications where hot control is very important.

What’s the difference: Aluminum PCB vs FR4?

FR4 is a standard fiberglass material used in many PCBs. Conversely, aluminum dressed boards using metals for bases, offering superior heat conduction. Aluminum boards are stronger, but FR4 is flexible for complex layer design. Choosing between them depends on the thermal needs of your project and mechanical demands.

How much is the price of PCB in aluminum dressed?

The price of aluminum dressed PCB depends on the size of the board, the thickness of the copper, the level of aluminum, and complexity. Although it may be more expensive than FR4 in raw materials, it saves costs in the heat sink and increase endurance. For prototypes that are cost -effective and small, the best technology offers competitive prices and fast shipping.

What are the specifications of PCB wrapped in metal?

The main specifications of a dressed metal PCB can vary depending on the application, but the typical range includes:

- Basic material: Aluminum alloys commonly used are 5052 and 6061, both offer good strength and thermal properties. While 3003 can be used, it is less typical because of its lower mechanical strength and thermal conductivity.

- Thermal conductivity: Standard PCB Aluminum Clad offers thermal conductivity between 1.0 to 2.0 W/MK. Higher values, such as 3.0 W/MK, are available but usually require special high thermal conductivity materials, which can increase costs.

- Copper thickness: Copper layers usually range from 1 oz to 6oz. The range of 1oz to 3oz is the most common, but a higher thickness is possible for the current application.

- The thickness of the board: Standard thickness ranges from 0.8mm to 3.2mm, but thinner boards, such as 0.6mmcan also be produced based on project needs.

- Final surface: Typical surface maintenance including HASL (leveling of hot air soldering), ENIG (gold soaking of electrical nickel), and OSP (Organic Solder Preservatives). The choice depends on the specific assembly process and performance requirements.

This specification allows PCB to be metal wrapped in providing efficient heat management and maintaining structural integrity in demanding conditions. However, the value must be adjusted to be in accordance with the real world operating environment for the best results.

What is the delamination of aluminum dressed PCB?

Delamination refers to the separation between layers. On the aluminum board, it can occur due to poor lamination or thermal stress. Using high -quality bonding materials and strict process control helps avoid this problem. The best technology uses sophisticated laminated techniques and thermal cycling tests to ensure reliability.

What is the purpose of aluminum dressing?

Clad Aluminum serves two main objectives: mechanical strength and heat management. It acts as a heat sink, pulling heat from components. It also adds rigidity, which is very helpful in high stressful environments such as automotive and industrial controls.

What are the advantages of aluminum PCB material?

Aluminum PCB material offers several benefits:

- Excellent thermal conductivity

- Increased endurance and support

- Reducing the need for additional heat sinks

- Cost effective in high power applications

- Light but strong structure

This advantage makes the aluminum PCB board ideal for LED lighting, power electronics, and the automotive sector.

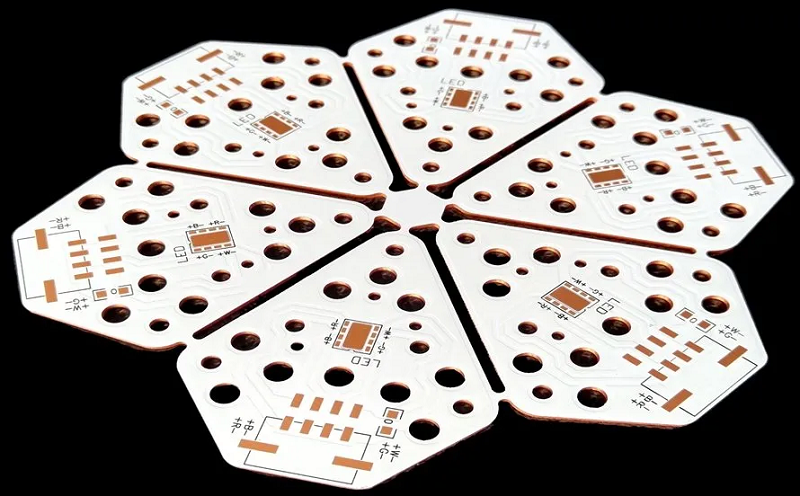

What is the aluminum PCB board for?

General use includes:

- LED lighting system

- Power supply and inverter

- Automotive lighting and control system

- Solar panels and power modules

Aluminum PCB boards for LEDs are very popular because of their ability to manage high heat from LED chips efficiently.

How to ensure the quality during the process of making aluminum PCB?

Quality control is the key. Steps include:

- Inspection of Materials – Make sure the quality of aluminum is consistent

- Appropriate drilling and etching – Maintain strict tolerance

- Thermal Testing – Validation of Heat Transfer Ability

- Visual Inspection – Check Delamination or Crack

The best technology uses the MES system for full tracking. Monitoring in our process ensures that each council meets strict quality standards, reducing customer defects and returns.

Why choose the best technology for aluminum PCB boards for LEDs?

Customers often face problems such as delayed shipping, unstable quality, or poor communication from suppliers. Most technology, we overcome this problem with a clear solution:

- Fast prototype: Fast turn service to meet a tight deadline

- Stable quality: Certified by ISO9001, ISO13485, and IATF16949

- Technical Support 24/7:English engineers and responsive support

- Customization:“Flexible for small or large volumes, special designs are welcomed

We offer an aluminum PCB attachment, full assembly, making boxes, and testing services to simplify the workflow of your project. With more than 1700 satisfied global clients, we have built a reputation for timely delivery and reliable product performance.

In closing, choosing the right partner for the needs of PCB wrapped in aluminum you can make or break your project time line and budget. The best technology offers complete solutions – from prototypes to final assembly. We understand your needs for clear speed, quality, and communication. With strict quality control and stable manufacturing processes, we help reduce risks and support your success. If you have questions about PCBs in aluminum, just tell us, let us know in aluminum, just tell aluminum, just tell aluminum, let’s tell the aluminum aluminum aluminum aluminum aluminum, enough aluminum aluminum aluminum [email protected] or +86-755-2909-1601. We will try our best to meet your needs. Whatever is made always get our response quickly.

Tag: aluminum dressed in pcb

This entry was posted on Monday, July 28, 2025 at 9:33 am and was submitted under the best PCB, BestTPCB, MCPCB, PCB Core Metal. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime