Look for that can be relied upon PCB assembly service? This guide includes the benefits, applications, suppliers of the recommended assembly and how to get offers to ensure the quality and efficiency for your project.

Are you worried about this problem?

- How to handle a postponement of PCB assembly delivery?

- How to overcome the increase in hidden costs in batch production?

- How to resolve post-sales complaints caused by fluctuations in the quality of suppliers?

As a PCB assembly manufacturer, the best technology can provide services and solutions:

- Advanced production scheduling systems allow 48 hours of fast prototype and 7 -day mass production delivery to solve the delivery problem.

- Modular design + mass procurement reduces bomb costs by 15%, while the production line automatically cuts the labor overhead by 30%.

- Three -stage quality control (First Article Inspection + SPC Monitoring + Full Lot Inspection) Ensures ≥98% results stability, reduce quality risk.

Welcome to contact us if you have a request for pcba services: [email protected].

What is a PCB assembly service?

PCB assembly service Refer to the process of making a professional installation of electronic components to the print circuit board (PCB) using surface-mount (SMT) technology or through hole technology (ENT), converting the naked board into a functional module or semi-finish product. Usually outsourcing by OEM or designer, this service requires design documents such as Gerber files and bomb lists. They serve various scale production, from prototypes to mass production, and are widely used in industries such as consumer electronics, automotive, and industrial equipment.

What are the advantages of PCB assembly services?

Below are the benefits of PCB assembly service:

Accelerated design validation

- The fast prototype (48-72 hours rotation) allows engineers to quickly test complex designs such as BGA packages and HDI routes, shorten the iteration cycle.

- DFM feedback helps prevent the weaknesses of general design (for example, inadequate PAD pad distances, stencil opening problems), reducing re -work costs.

Supply chain risk mitigation

- Service providers handle component procurement (including EOL parts), inventory management, and price volatility, engineers freed from the coordination of supply chains.

- The purchase of bulk reduces material costs (up to 10-30% savings) while ensuring authentic components.

Advanced process skills

- High precision equipment (for example, accuracy of placement of 0.025mm, 01005 micro package) allows engineers to encourage design limits.

- The expert team optimizes solder parameters (for example, reflow nitrogen) to increase reliability for high frequency/high -speed PCB.

Improved quality control

- Full process testing (AOI/X-Ray/ICT) automatically detects soldering defects (for example, cold connections, bridging), reduce quality control loads.

- In accordance with ISO/IATF standards, simplify certification for medical, automotive, and demanding applications.

Flexibility of production that can be discuted

- The smooth transition from a small prototyping batch (50+ units) to mass production, adapted to the needs of the product life cycle.

- The quick response to the urgent order through capacity allocation, ensures a critical project deadline.

What problems can be solved by PCB assembly services?

PCB assembly service Overcoming several challenges in electronic manufacturing, including:

- Design Implementation Barriers: Overcoming the challenges of physical realization such as high density (for example, pitch BGA 0.2mm) and irregular component layout through professional cam engineering.

- High prototype costs for small batch: Flexible low minimum order solutions (out of 50 units) eliminate high tool costs and MOQ resistance during validation.

- Special Process Requirements: Activate advanced techniques: blind/buried, heavy copper (6oz+), ceramic substrate – exceed the laboratory fabrication limit.

- Supply chain management components: Automatically the source of the global channel inventory, resolving chip deficiency/eol/fake risk problems.

- Hybrid assembly requirements: Integrate SMT + ENT + Soldering Hand for Complex PCBA with high power connectors/devices in one pass production.

- Inadequate test resources: Provide development of professional ICT/FCT equipment, compensate for the DFT gap (design for testability) in the R&D team.

- Standard Risk Compliance: ISO 13485/IATF 16949 Certified Lines Prevent Certification Failure in Medical/Automotive Applications.

PCB assembly service application

PCB assembly services are used in various industries and applications, such as:

- Consumer Electronics: Smartphones, tablets, and items that can be worn.

- Industrial Equipment: Automation system and control unit.

- Automotive Electronics: Sensors, infotainment systems, and ECU.

- Medical devices: Diagnostic equipment and monitoring systems.

- Telecommunication: Router, modem, and network device.

Our PCB assembly service

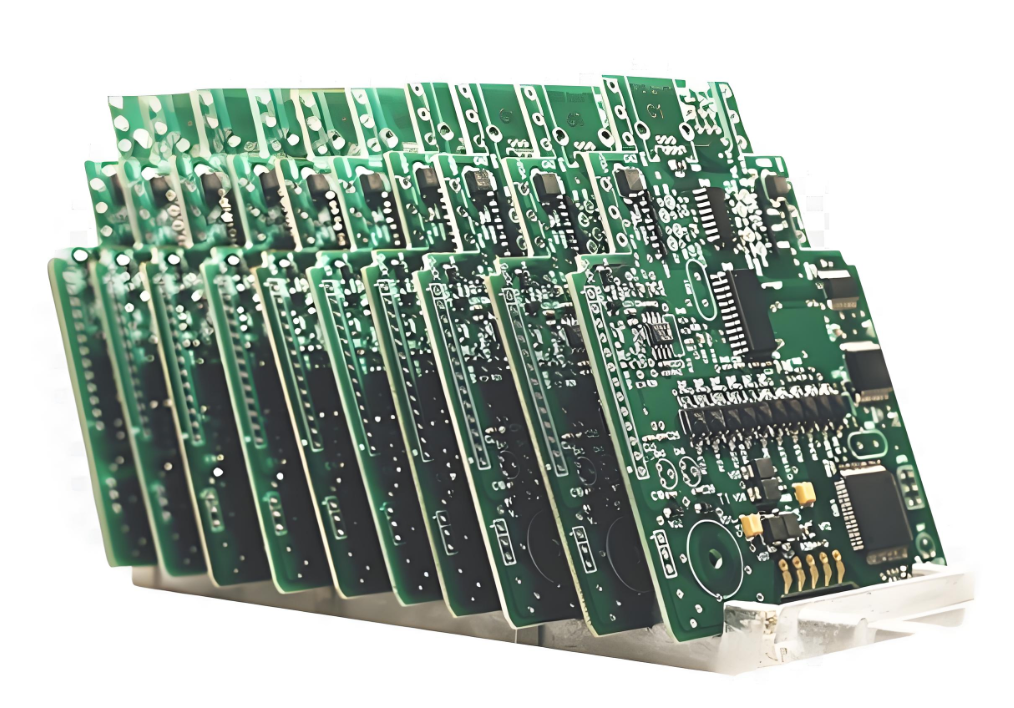

In the best technology, we offer a variety of PCB assembly services To meet your needs:

- SMT Council: Advanced SMT line for the placement of the right component.

- Thru-Hole Council: Handling traditional thru-hole components.

- Turnkey assembly: End to end solution, including the source and component testing.

- No MOQ: Flexible service without minimum order quantity requirements.

- Comprehensive inspection: DFM/DFA examination, testing of functions/ICT, X-ray, and AOI inspection.

Why choose the best technology as a PCB assembly manufacturer?

The reason why choosing us as PCB assembly manufacturer:

- 19 Years of PCBA Expertise: Specifically in the PCB assembly for 19 years, handling complex designs from prototypes to mass production with 99.8%results stability.

- Turnkey Solution: Full chain solutions from PCB inspection, component sources, SMT/DIP assembly, testing for packaging, sending designs, receiving PCBA that are ready to be marketed.

- Yamaha high -speed equipment: Equipped with the Yamaha SMT Japan path for the 01005 component and precision pitch BGA 0.3mm, meets miniature demand.

- Four Parallel Production Paths: Flexible scheduling for fast prototypes (48 hours) and volume production that can be discharged, speeding up time-to-market.

- Real-time tracking: Digital tracking that is driven by MES for the visibility of the process 100%-Monitoring Progress, Test Reports, and Quality Data remotely.

- Certified quality control: ISO 9001/IPC-A-610 appropriate, with AOI/X-Ray inspection ensures zero defects and the readiness of the EU/US market.

- Bilingual Technical Support: Direct technical communication with foreign engineers to minimize the design gap in design and process risks.

- Fast Prototype 24 Hours: Fast rotation prototype for design iterations, shortening the development cycle.

- Environmentally friendly process: Solder free lead and spirit compliance/reach for global environmental regulations.

- Global Logistics Network: Partner with DHL/UPS for PCB delivery that is assembled worldwide and efficient.

Our PCB assembly capability

| Goods | Ability |

| Placer speed | 13,200,000 chips/day |

| Naked board size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD component | 01005 |

| Pitch BGA Minimum | 0.25mm |

| Maximum component | 50*150mm |

| Type of assembly | SMT, ENT, Mixed assembly |

| Component package | Rolls, cut ribbons, tubes, trays, loose parts |

| Waiting time | 1 – 5 days |

What is the difference between PCB assembly services from other solutions?

Assembly at home

- Feature: Requires to build a full production line with equipment such as SMT machines, AOI inspection systems, and DIP plug-in tools, along with special engineering teams.

- Profit: Full control of the production process, quality standards, and technical confidentiality, ideal for high security products (for example, military, medical devices) or large -scale stable mass production.

- Challenge: High initial investment (equipment, factories, labor costs) and sustainable maintenance/improvement costs; Small batch production leads to a much higher unit cost compared to outsourcing, with delaying potential technology iterations.

Outsourcing Council

- Feature: Entrusting professional PCBA manufacturers to handle partial or full assembly processes, utilizing adult technology, economy scale, and supply chain resources.

- Profit: Reduce investment in fixed assets and adapt flexiblely to small-variety of small batch orders; Allows fast access to advanced processes (for example, HDI, micro-BGA packaging); Reducing costs through procurement centered by suppliers, especially suitable for the needs of R&D that is nimble from SMEs.

- Challenge: Requires strict inspection from suppliers qualifications (for example, ISO certification, IPC standard) to avoid quality risk; Coordination costs for logistics and communication can cause delays in response.

Turnkey Solution

- Feature: Offering end-to-end services that include bomb sources, PCB fabrication, component placement, functional testing, and logistics delivery. Clients only need to provide design files to receive complete products.

- Profit: Greatly simplify the client’s management process and shorten the project cycle (for example, a 48 -hour fast prototype); Achieve full tracking through a digital system (for example, DFM verification, transparent progress dashboard) to minimize human errors; Reducing bomb costs by 15%+ through centralized procurement and optimization of supply chains, dealing with “minimum order quantity” and “hidden costs” for small batch.

- Application scenario: Ideal for the fast prototype in the R&D phase, the production of trial-small tests, nimble manufacturing varies, and innovative projects that require strict cost control and fast-market-time.

How do you get an offer for PCB assembly service?

To get offers for PCB assembly services, you need to send the following list of material:

- Gerber File: Standard format for PCB design data.

- Bill of Material (Bomb): Complete list of components with reference number, number, and reference designer number.

- Pick-and-Plase file: Files that can be read by machines for component placement (eg. CSV, .TXT).

- Assembly image: Visual guide for component placement and orientation.

- Special Instructions: Any unique requirements (for example, conformal coating, testing protocol).

- Quantity & Waiting Time: Estimated volume of order and time completion required.

Contact us today

If you have questions about our PCB assembly service or want to ask for an offer, don’t hesitate to contact us: [email protected]. We are committed to providing the best quality, price, and service to meet your PCB assembly needs.

Tag: PCB assembly manufacturer, PCB assembly service

This entry was posted on Monday, September 29, 2025 at 10:26 am and was submitted under the best PCB, BestTPCB, FR4 PCB, MCPCB. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

News

Berita

News Flash

Blog

Technology

Sports

Sport

Football

Tips

Finance

Berita Terkini

Berita Terbaru

Berita Kekinian

News

Berita Terkini

Olahraga

Pasang Internet Myrepublic

Jasa Import China

Jasa Import Door to Door