Isola 370HR is an established choice for engineers who need a durable and compatible PCB base material with high frequency. TG is high, low loss, and excellent reliability makes it suitable for everything, ranging from aerospace to telecommunications.

If you are working on a complex design or RF application, switching to the ISOLA 370HR PCB material may be an increase that you need. And with reliable partners like the best technology, you are sure of the quality of the first prototype to volume production.

What is the 370HR ISOLA material?

Isola 370HR is a high and high and high -performance epoxy laminate system developed by the Isola group. Specifically designed for multilayer printing circuit boards, it offers a large balance between electricity stability and thermal durability. This is classified as high TG FR4 material but provides better signal treatment and thermal behavior compared to FR4 standard.

Isola engineered this material for demanding sectors such as telecommunications, data networks, and military electronics. Low loss of dielectric and stable performance in a broad frequency range makes it suitable for modern high -speed circuits.

The advantage of using Isola 370HR on PCB Manufacturing

Choosing Isola 370HR for your PCB Manufacturing Brings some of the main benefits that directly affect the performance and reliability of your finished product:

- Superior thermal stability: with high glass transition temperatures (~ 180 ° C), 370 hours of high temperature of high temperatures of leaders and some reflow cycles without warping or delamination.

- Low dielectric loss: This material minimizes signal loss at high frequency, making it perfect for RF circuits and high -speed digital design.

- Very good signal integrity: Stable Dielectric Constant (DK) across the frequency range means consistent signal propagation and time error reduction.

- Increased humidity and caf resistance: Increased resistance to failure that is induced humidity helps maintain long -term reliability, especially in humid or hard environments.

- Dimensional stability: Reducing the expansion of the Z axis ensures that the layer remains in harmony during the manufacture and operation, it is important for the multilayer PCB.

- IPC Compliance: Isola 370HR meets strict industrial standards, ensuring compatibility with demand, automotive, and medical aerospace applications.

- Rohs and Environmental Compliance: fully in accordance with environmental regulations, supporting the practice of green manufacturing.

Isola 370HR Datasheet

| Owned by | Typical value | Test methods / notes |

| Glass transition temperature (TG) | 180 ° C (DSC) | Calorimetry of differential scanning |

| Decomposition Temperature (TD) | > 340 ° C. | TGA (Thermogravimetric Analysis) |

| Dielectric Constant (DK) | 4.04 @ 1 GHz | IPC-TM-650 2.5.5.5 |

| DISCIPATION FACTORS (DF) | 0.0127 @ 1 GHz | IPC-TM-650 2.5.5.5 |

| Thermal Expansion Coefficient (CTE) | 15 ppm/â ° C (xy), 65 ppm/â ° C (z) | IPC-TM-650 2.4.24 |

| Thermal conductivity | 0.4 W/Mâ · K | ASTM E1461 |

| Tensile strength | 24,000 PSI | IPC-TM-650 2.4.18 |

| Flexible power | 32,000 PSI | IPC-TM-650 2.4.4 |

| Water absorption | <0.10% | IPC-TM-650 2.6.2.1 |

| Flammable ranking | UL 94 V-0 | Ul 94 |

| The power of copper peel | > 1.0 lbs/inch | IPC-TM-650 2.4.8 |

| Surface resistivity | > 1 × 10^6 ohms | ASTM D257 |

| Volume resistivity | > 1 × 10^9 Ohm-cm | ASTM D257 |

| Dielectric damage voltage | > 50 kV/mm | IPC-TM-650 2.5.6 |

What is the difference between FR4 and 370 hours?

While the 370 -hour FR4 and Isola standards are epoxy -based materials that are widely used in making PCBs, they differ significantly in performance – especially when coming to high -speed applications and high frequencies.

The standard FR4 is the incoming material for many general purposes PCB. It offers decent mechanical strength, good manufacturing, and cost effectiveness for daily electronics. However, the temperature of the glass transition (TG) usually ranges from 130 ° C to 140 ° C, and has a relatively higher dielectric loss (DF). These limitations can cause signal degradation and reliability problems in circuits that operate at higher frequencies or high temperatures.

Conversely, Isola 370HR is a high TG FR4 variant designed to meet more challenging environmental demands. The TG is around 180 ° C, which provides superior thermal stability during the lead-free polishing and extended use in high temperature regulation. More importantly, this shows the lower dielectric constant (DK) and the Disipation Factor (DF), which is translated into lower signal loss and better signal integrity at the frequency of micro and radio waves.

Why is PCB Isola 370HR suitable for high frequency applications?

When electronic devices develop to support faster data rates, PCB material performance in high frequency conditions has become a serious concern. This is where the ISOLA 370HR PCB material shines.

Consistent dielectric constant (DK) and low discipline factors (DF) ensure that high frequency signals do not lose strength or become distorted. That’s the main reason why 370 hours are used in:

- Ethernet gigabit system

- High -speed backplanes

- Automotive radar system

- Satellite communication

- Sophisticated test equipment

Its ability to deal with GHz level signals without distortion helps maintain data accuracy and reduce problems related to EMI.

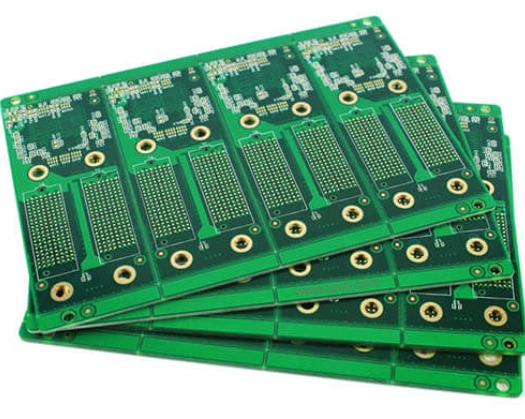

When to choose the 370HR isola material for your PCB?

You might consider the Isola 370HR when your design is included in one of the following categories:

High -speed design or RF: If your circuit runs more than 1 GHz, this material can maintain signal quality.

- Multilayer PCB: When piling up 8 or more layers, 370HR offers control and great registration stability.

- Thermal voltage tolerance: This is a reliable performing through several reflow cycles and extreme temperatures.

- CAF resistant needs: Ideal for products exposed to moisture or long -term use.

- Strict Industrial Compliance: Meet IPC-4101/126 and 129, as well as UL and ROHS requirements.

Choosing this material is not about performance about the peace of mind over the product life cycle.

How do I identify the original 370HR ISOLA PCB material?

To avoid fake materials or substitutes that are not verified, it is important to:

- Ask for the original data sheet with the Isola logo and batch number.

- Check the board sign to identify the Isola brand or the laminated code.

- Working with certified suppliers who buy directly from official isola or distributor.

- Ask the certification document, especially if your application is regulated by aerospace or medical standards.

- Original 370HR ISOLA PCB material ensures consistency in production and performance.

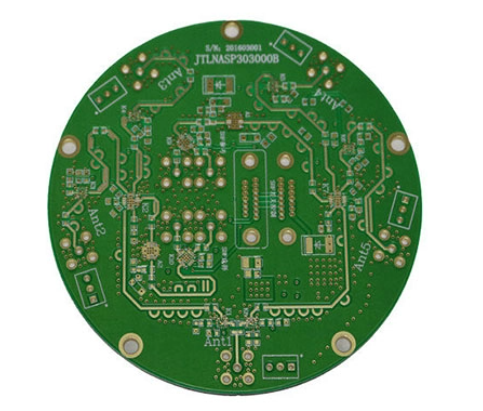

Typical Application of Isola 370Hr in PCB Design

The following are the industry and general devices where the 370HR ISOLA is often used:

- Telecommunications: High -speed switches, routers, and optical fiber systems.

- Aerospace and Defense: Radar, Avionics, Satellite Boards.

- Medical equipment: imaging devices, patient monitoring systems.

- Automotive: Advanced Driver Assistance System (FASE), Lidar Module.

- Industrial automation: motor control, power management system.

Designers throughout the sectors depend on thermal reliability and signal control to reduce field failure.

What is equivalent to Isola 370HR?

While Isola 370HR is a preferred material, there are other options that offer similar characteristics. Here are some alternatives that are compared:

| Material name | TG (° C) | Df @ 1ghz | Important features |

| Nelco N4000-13Ep | ~ 180 | ~ 0.013 | Known for stability |

| Panasonic Megtron 6 | ~ 185 | ~ 0.0025 | Loss is very low, but expensive |

| Ventec VT-47 | ~ 180 | ~ 0.014 | Cost -effective option |

If you need a better electricity performance than 370 hours, Megtron 6 is a good choice. For high frequency use in general with cost control, 370 hours remain the most balanced choice.

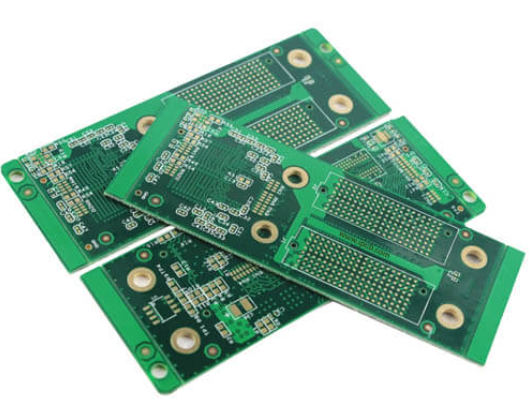

Why choose the best technology for the PCB Isola 370HR manufacturing?

With more than 18 years of experience on the printed circuit board and as one of the leading PCB manufacturers, we support more than 1,000 customers in various industrial areas around the world. You can rely on PCB board manufacturers like us to meet your one -stop electronic manufacturing demand.

We are your one -roof PCB manufacturer in China that can meet all of your diverse PCB requirements. We have experienced quality, production and quality engineering teams that fully understand the unique needs of your industry ‘, especially in medical, automotive, and aerospace applications. As a printed circuit board manufacturer, we can also demand your Fabrication 2 or your IPC, and your IPC.

If you have questions about products, services, prices, waiting time, quality control, certification, or our technical support, don’t hesitate to contact us at any time. Our goal is to be one of the best PCB manufacturers in China, offers extraordinary quality, fair prices, and professional services.

FAQ

1. Is Isola 370 hours good for the RF application?

Yes, he offers low dielectric loss and stable DK, perfect for high frequency circuits.

2. How is the 370HR Isola different from the standard FR4?

It has a higher TG, better thermal stability, and lower signal loss.

3. What industry uses the ISOLA 370HR PCB material?

Telecommunications, automotive, derivative, medical, and industrial electronics.

4. Can 370 hours support lead to lead to lead?

Yes, this is entirely compatible with RoHs and the process of leaders free of lead.

5. Where can I get an offer for Fabrication of PCB Isola 370HR?

Contact the best technology for custom, custom quotes and expert support.

Tag: Isola 370HR PCB High Frequency, Isola 370HR PCB

This entry was posted on Wednesday, July 2, 2025 at 17:52 and submitted under the best PCB, BestTPCB, FAQ, FR4 PCB, PCB News, PCB Technology, PCBA. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-07-03 01:27:21.