When the engineer starts a new project or graduation student wants to complete the graduation project, one of the first questions they ask is: How much does the PCB board cost? The answer depends on several factors such as size, layer, material, and whether assembly is included. Whether you do a prototype or mass producing, understanding the price of the PCB council helps you budget better and avoid hidden costs. In this guide, we will break the basic prices of PCB boards, answer some of the most common questions, and show you how to save money without reducing quality.

What is the difference between the circuit board and PCB?

Before breaking the cost of PCB, let’s explain the difference between the circuit board and PCB. Although people often use this term in turn, there is a slight difference. Circuit board is a general term that can refer to any board used in electronic devices.

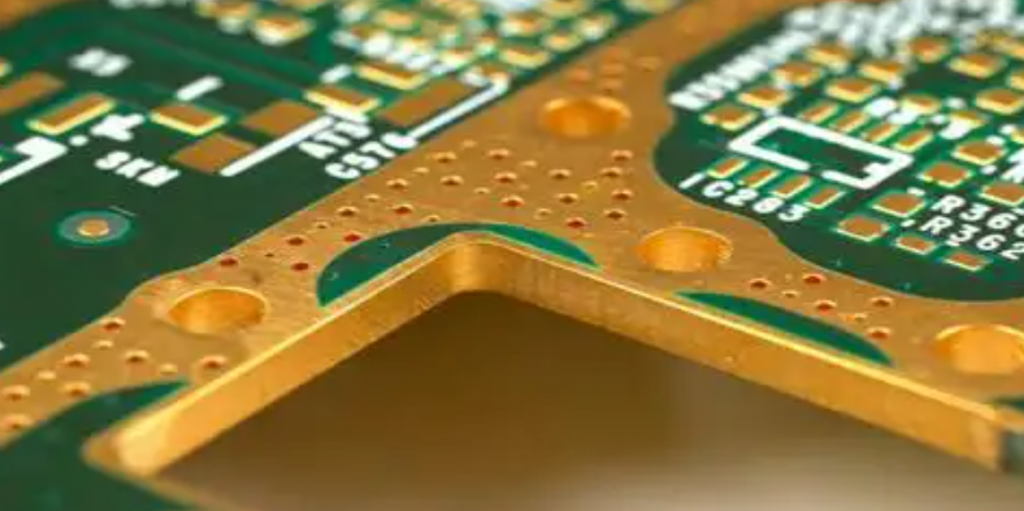

PCB (print circuit board) is a specific type that uses a conductive track that is engraved into the substrate, usually FR4 or ceramic. All PCBs are circuit boards, but not all circuit boards are PCBs. When we talk about the price of PCB boards, we usually mean boards produced professionally and are ready to install components.

How much does PCB cost per square inch cost?

On average, the price of PCB boards per square inch ranges from $ 0.50 to $ 5, depending on the complexity and size of the order. For PCB two base layers made in large volumes, the cost can be at the bottom end. But for high frequency, multi-layer, or special material boards, the price goes up.

| PCB type | Price per square inch |

| PCB FR4 2-Basic Repair | $ 0.50 – $ 1.00 |

| PCB 4-Lather | $ 1.50 – $ 2.50 |

| 6+ PCB layers | $ 2.50 – $ 4,50 |

| Ceramics or metal core | $ 3.00 – $ 5.00+ |

These prices vary based on the manufacturer, waiting time, end of the surface, and test requirements.

What factors affect the price of PCB boards?

Some factors play an important role in determining the price of the PCB board, the most influential factors include:

1. Number of layers

The more layers the PCB has, the higher the cost. 2 -layer board is relatively cheap to make, but when you move to 4, 6, or even 10 layers, complexity increases significantly. Each additional layer means more laminated cycles, drilling, and alignment steps.

2. Size and shape of the board

Larger boards use more materials, which raise the price. An unusual form that requires non-standard stomach also increases manufacturing complexity, sometimes requires special tools or manual cutting.

3. Material selection

FR4 standard is the most cost -effective material. However, special substrates such as ceramics, aluminum, polymide, or Rogers laminate are much more expensive. This is often used for high frequency or heat application and increases the total cost.

4. Traces of the width and distance

High density design with narrow traces and tight distances requires more appropriate manufacturing, which involves a sophisticated process and tighter quality control. That adds costs due to increased difficulties and the possibility of loss of yield.

5. Final surface

The final results such as HASL (Leveling Solder of Hot Air) economical, while others such as Enig, Eneig and Silver Soaking Increases durability but come at premium prices. The choice depends on the soldering process and environmental conditions.

6. Via type and count

VIAS through the hole is cheaper, but blind and buried Vias, microvias, or via-in-PAD structure adds to the steps of drilling and additional lamination. This special VIAS is common on the HDI board (high density interconnection) and encourages higher costs.

7. Solder Mask Color

Green is standard and the cheapest. Other colors such as red, black, white, or blue may be a little more expensive. Clear or custom colors are rare and are usually valued higher.

8. Turnaround time

Short waiting times often require priority in production queues and overtime workers, which increase costs. The standard production schedule offers a better price if you are not in a hurry.

How much does the PCB assembly cost?

The price of the PCB board does not include assembly unless specified. PCB Assembly (PCBA) adds labor, use of equipment, and component sources into costs. Average:

- Simple board (less than 50 components): $ 5 – $ 20 per board.

- Medium complexity: $ 20 – $ 30 per board.

- High complexity or low volume with many components: $ 30+ per board.

For large running, prices fall significantly, often down to several dollars per board for simple designs. Using the Turnkey assembly (where manufacturers handle all) are usually cheaper in large quantities.

How to reduce the cost of PCB on a printed circuit board?

Here are some proven ways to reduce the price of your PCB board without sacrificing quality:

1. Design with standard board size, FR4 material, and general thickness (1.6mm) to avoid customization costs.

2. Reduce the number of layers if possible. Re -use the reference design or optimize the layout to avoid unnecessary complexity can significantly reduce production costs.

3. If you order a small PCB, ask for your manufacturer to line up several boards in one larger sheet. This can increase production efficiency and reduce costs per unit.

4. Unless you need advanced protection or plan some polishing cycles, HASL can be a suitable and affordable end result.

5

6. High volume production significantly reduces costs per unit. If you can predict demand, batch your order for a better price.

Working with experienced and flexible PCB manufacturers such as Best Technology allows you to get valuable feedback about opportunities for cost saving without compromise. We provide a full DFM check to avoid re -work costs.

How do I choose a PCB board?

Choosing the right PCB for your project helps ensure reliability while controlling the price of the PCB board. This is what must be considered:

1. Application requirements

If you are working on consumer products, the standard FR4 board will do it. But for high -power LEDs, RF circuits, or automotive electronics, you may need special materials such as Rogers, Dupont.

2. Electric performance

Check whether your circuit demands controlled impedance, high frequency transmission, or thermal management. The right material and layout will support this without unnecessary costs.

3. The size and density of components

The strict space or miniature design may require multi-layer boards or HDI technology. Choose your number of layers based on how crowded your design is.

4. Budget and volume

For low volume projects, it is often better to work with producers who support batch services or small prototypes. For the production process, choose vendors that offer prices that can be discussed.

For most general electronics, 2-lips FR4 PCB will do the job. But for high -power LEDs, RF applications, or miniature devices, materials such as aluminum, ceramics, or Rogers laminate may be needed. Consult with professional PCB manufacturers such as the best technology to get cost -effective and reliable solutions that are tailored to your needs.

What is the most common PCB thickness?

Industrial standard for PCB thickness is 1.6mm (0.063 inches). It offers a good balance between mechanical strength and space savings. However, depending on the application, PCB can range from 0.4mm to more than 3.2mm.

Can I make my own PCB board?

Yes, you can make a basic PCB at home using copper boards and etching chemicals. But the DIY board is only suitable for low frequency applications and is not critical. They do not have accuracy, durability, and reliability of professional boards.

If you need a consistent performance, especially in multi-layer or pitch design, outsourcing to PCB fabrication specialists is the best route. In the best technology, we offer a cost -effective PCB solution with fast turnaround and strict quality control. Whether you do a prototype or improve, our technical team is here to help.

FAQ

1. Is it cheaper to order PCB from China?

Yes. Many Chinese manufacturers like the best technology offer excellent prices and quality because of the economy scale and efficient production paths.

2. Can I get a single PCB prototype?

Very. Many companies offer low volume orders or one part for prototype purposes.

3. Does the price of PCB include components?

Not usually. The price of the PCB council refers to the naked board. Assembly and components are charged separately.

4. Is Enig Completed Combat with Additional Fees?

If you need a better surface level, corrosion resistance, or plan some reflows, Enig is a good investment.

5. What is the waiting time for making a PCB?

The standard is 5 ‘7 days. The express option ranges from 24 to 72 hours, depending on the producer.

Tags: PCB board fees, PCB board prices

This entry was posted on Wednesday, June 18, 2025 at 18:12 and submitted under the best PCB, BestTPCB, FAQ, FR4 PCB, PCB News, PCB Technology. You can follow any response to this entry through RSS 2.0 bait. You can leave a response, or trackback from your own site.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-06-18 10:32:50.