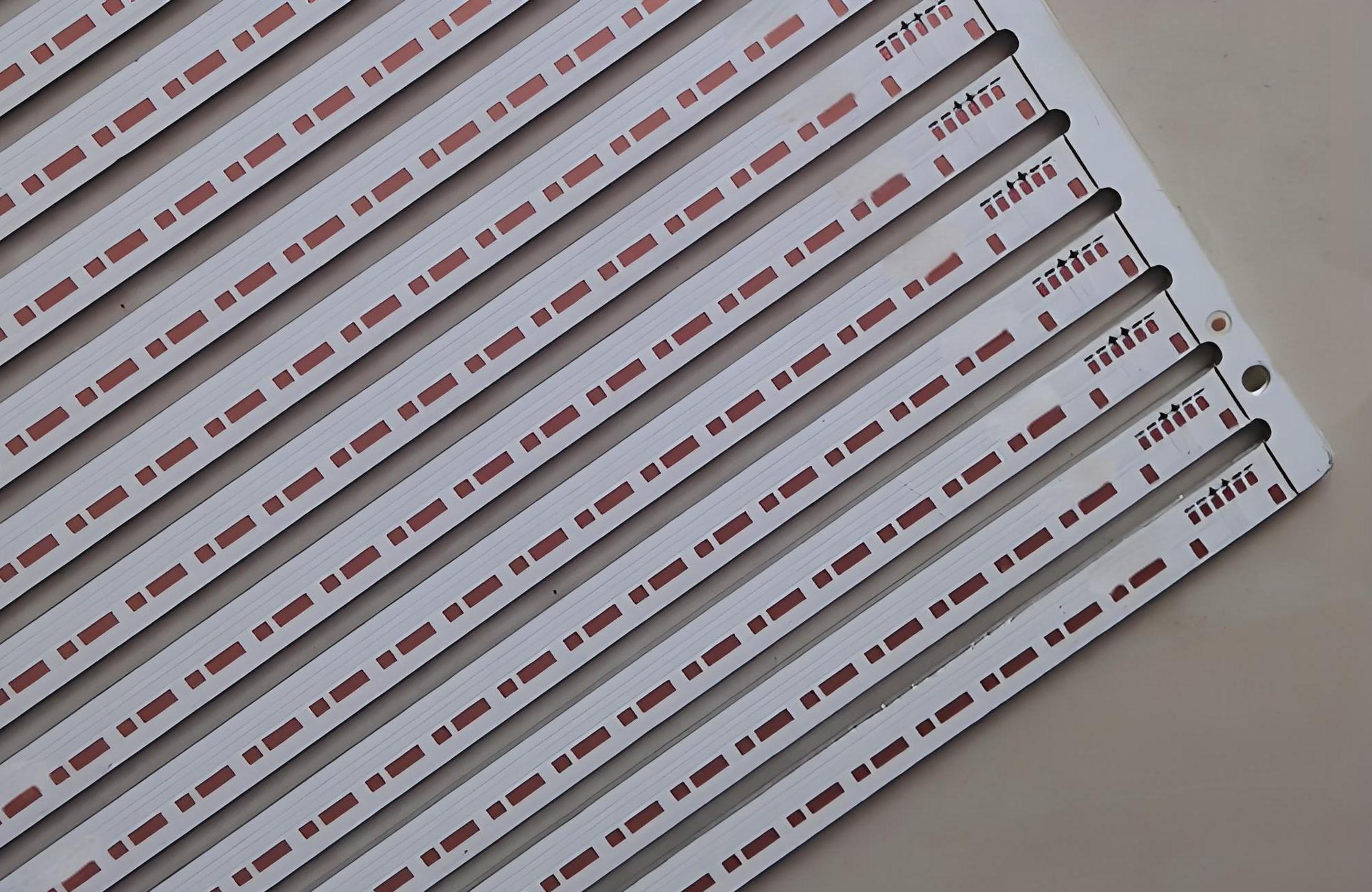

Double LED aluminum substrate is a high thermal conductivity circuit board with copper cables on both sides of the aluminum substrate. LEDs are soldered on one side and the drive circuit or control is done on the other side. The aluminum core in the middle removes heat quickly, allowing high-power lamp beads to operate stable in a smaller space. It has been widely used in automotive lights, street lights and high -density backfront modules.

Are you curious about the best two -sided aluminum aluminum substrate technology?

- Will the two -sided cable lead to a short circuit or signal distortion due to inaccurate interconnection?

- Is the heat dissipation balanced on both sides, preventing localized hot heat that can affect the life of the lamp?

- Will the copper foil be easily peeled after the solder repeatedly?

- Does two -sided processing costs confirm performance improvement?

The best two aluminum aluminum substrates can answer these questions.

- Using a high precision drilling and alignment process, interconnection holes are positioned appropriately, provide reliable isolation and prevent short circuits or signal problems.

- The basic design of two sides aluminum, with symmetrical heat dissipation paths, ensures even heat conduction, reduces excessive heat, and extending the life of the lamp.

- The foil and aluminum base of copper is tightly bound through a high temperature pressing process, resistant to the heat of solder and maintain stable adhesion after the solder is repeated.

- The two -sided design increases the density of the circuit and the efficiency of heat dissipation. The cost process is optimized through large scale production, and an increase in performance is far greater than the increase in costs.

What is a double side aluminum PCB?

The two -sided aluminum PCB is a printed circuit board with aluminum as its basic material, displaying copper layers on both sides. This includes a dielectric layer of insulation between copper and aluminum base. This design allows stomach on both sides, unlike one -sided board that only allows traces on one side.

Because aluminum offers excellent heat dissipation, this board is widely used in high -power LED lighting. They prevent overheating, which can damage LEDs or reduce their age.

With two conductive layers, the two -sided board also allows a more complex circuit, making it ideal for advanced LED assemblies.

Type of aluminum pcb two sides

Two -sided aluminum pcb Come in various forms, depending on the needs of the application. The most common types include:

- Aluminum PCB Two Standard Sides: It has two copper layers and dielectric layers between the base of the aluminum. They are simple but effective for medium power applications.

- PCB Two Hybrid Side: This type of substrate combines the benefits of two different materials, such as aluminum and ceramics, to provide an increase in thermal conductivity and electricity performance.

- PCB Two Flexible Side: This type of substrate is made of flexible material and has an aluminum layer on both sides. This is usually used in applications where flexibility is needed, such as electronic that can be used.

- PCB Aluminum Two Side High Frequency: This type of substrate is designed for high frequency applications and has a low dielectric constant, which helps reduce signal loss.

Each type serves a specific purpose. Choosing the right depends on thermal needs, the complexity of the circuit, and mechanical needs.

How is the two -sided aluminum PCB different from one side?

Aluminum PCB One Side It has a copper layer for the stomach circuit, limiting its complexity. The two -sided board, on the other hand, has two copper layers, allowing the placement of components that are denser and more sophisticated designs.

Another main difference is thermal management. Both of them provide excellent heat dissipation thanks to the basic aluminum, but the two -sided board handles a higher power load better. This is very important for a very open LED system where heat can accumulate quickly.

Finally, cost and assembly are different. The two -sided board may be more expensive.

What ingredients are used in the two -sided LED aluminum substrate?

Double LED aluminum substrate usually consists of:

- Aluminum base layer: Provide excellent structural strength and thermal conductivity.

- Dielectric layer: Acting as an insulator between the aluminum base and the copper layer while offering high thermal performance.

- Copper foil: Present on both sides for the stomach circuit. Thickness varies depending on the current requirements.

- Solder Mask: Protect copper from oxidation and prevent short circuits.

- Silkscreen layer: Used for labeling components and guiding assembly.

Some boards may also include surface layers such as Enig (Electric Nickel Soaking Gold) for better solderiability and corrosion resistance.

What are the benefits of using two -sided LED substrates compared to FR4?

Compared with FR4 boardThe two -sided aluminum substrate has many advantages:

- Superior heat dissipation: Aluminum does heat from LED quickly, reduce thermal stress.

- Power is increased: Aluminum -based boards are more resistant to mechanical stress than FR4.

- Handling better strength: Perfect for high -power LED applications where FR4 cannot manage heat efficiently.

- Longer LED life: Lower operating temperatures means LEDs are longer, reduce replacement costs.

- Compact design: Two -sided routing allows smaller and more efficient layout.

While FR4 is common in electronics, it cannot match the aluminum substrate for thermal and structural performance in the LED system.

What thickness options are available for two -sided LED aluminum boards?

Thickness plays an important role in thermal performance and strength. Typical options include:

- Aluminum basic thickness: 1.0 mm, 1.2 mm, 1.5 mm and 2.0 mm.

- Copper thickness: Usually 1 ounce (35 μm), 2 ounces (70 μm), or even higher for high current applications.

- Dielectric layer: Often between 75 μm and 150 μm, depending on thermal needs.

Choosing the right thickness ensures the right heat dissipation without adding unnecessary weight.

Where is the two -sided aluminum substrate used?

Two -sided aluminum substrate multipurpose. General applications include:

- LED lighting system: Indoor, outdoor, and industrial lighting where thermal management is very important.

- Automotive lighting: Headlamps, tail lights, and dashboard lighting.

- Consumer Electronics: Devices that need a compact but heat -resistant board.

- Medical devices: Surgical lights and diagnostic equipment that must remain cold for safety.

- Power Electronics: High power converter and power supply where heat is the main concern.

The ability to deal with high power and maintain stability under the heat makes this substrate important for sophisticated applications.

How is the two -sided aluminum PCB produced?

The manufacturing process involves the right steps:

- Basic Aluminum Preparation: The base is cleaned and cared for to increase adhesion.

- Dielectric layer application: The thermal conductive layer but electric isolation is added.

- Copper foil lamination: Copper is laminated on both sides under the heat and pressure.

- Circuit pattern: Copper layers are engraved to make circuit paths.

- Drilling and coating: The hole is drilled and layered to connect the layer.

- Surface finishing: ENIG, HASL, or other final results are applied to better solderability.

- Soldering mask and silkscreen: Applied to protection and labeling.

- Testing: Each board undergoes electricity and thermal testing to ensure quality.

Precision is the key to achieving strict tolerance and durable performance.

What is the two -sided aluminum PCB application?

This board gives power to various industries:

- LED lighting: Street lights, spotlights, and intelligent lighting solutions.

- Display and signage: Show high firmness that runs for hours.

- Telecommunications equipment: Devices where hot controls are very important for reliability.

- Aerospace and Defense: Applications that require endurance and extreme stability.

- Renewable energy: Solar inverters and power control systems that demand high thermal performance.

Wherever the heat and reliability of the material, the two -sided aluminum PCB is an entry solution.

Conclusion:

Two -sided aluminum substrate for LEDs Able to handle high power, eliminate heat efficiently, and support compact design without sacrificing performance. Their advantage compared to FR4 makes it the best choice for demanding applications.

If you need a special aluminum LED substrate for your project, the best technology is here to help. We provide premium quality aluminum PCBs, tight quality controls, and fast shipping. Contact us today at [email protected]

Tag: two -sided LED strip, two -sided LED aluminum LED, LED substrate

This entry was posted on Friday, August 22, 2025 at 14:57 and was submitted under the best PCB, BestTPCB, MCPCB, Metal Core PCB. You can follow any response to this entry through RSS 2.0 bait. You can jump to the end and leave a response. Pinging is currently not permitted.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime

Gaming Center

Originally posted 2025-08-22 08:06:53.