Why choose 6oz Aluminum PCB For electronic control boards? Let’s explore the benefits, applications, technical specifications, thermal management, production process for 6oz aluminum pcb.

Are you having a problem with this problem?

- Too hot causes frequent failures and high repair costs?

- Poor PCB’s Thermal Performance Limits Product Improvement?

- Small batch orders struggle with slow shipping and inventory risk?

The best technology can provide services and solutions:

- Thermal management of high efficiency: significantly extend the life of the device.

- Rapid prototype: 48 hours of fast prototype and flexible support for small batch orders.

- Cost Optimization: Integrated thermal design reduces overall system costs by 25%.

Welcome to contact us if you have questions for aluminum pcb: [email protected].

Why choose 6oz aluminum pcb for electronic control boards?

Reasons why choosing 6oz Aluminum PCB For electronic control boards:

- Powerhouse of Hot Dissipation: Thermal conductivity> 2.0W/m · k. Reducing component temperature by 40% vs. FR4.

- Current performance is high: 6oz copper (0.17mm) handles high power loads. Minimize the decrease in voltage on the motor drive/power module.

- Light & Durable: Aluminum Alloy (6063/5052) balances strength and weight. Resistant to the vibration/industrial environment.

- EMI Shield: Reducing high frequency noise on the RF/5G circuit. Increase signal integrity with a foundation design.

- Cost -effective design: Eliminating heatsinks/fans. Activating compact layout for board restricted space.

- Sturdy reliability: Passing extreme thermal cycling (-40 ° C ~ 125 ° C). Surface Finishes (ENIG) Corrosion resistant.

- Production that can be discussed: The thickness of copper is consistent for high yields. A layer that can be adjusted to the needs of various control boards.

Aluminum 6oz PCB Application For EV Electronic Control Board

- Motorcycle Control Power Module (MCU)

- Charger On-Board (OBC) DC-DC Conversion Circuit

- The main board of the battery management system (BMS)

- Inverter power unit

- PDU (Power Distribution Unit) Busbar

- VCU (Vehicle Control Unit) Power Module

- Thermal-sensitive sensor interface board

- Fast charger power module

6oz aluminum pcb for electronic control board design specifications

| Parameter category | Specifications/Details |

| Substrate material | 6063/5052 aluminum alloys (high thermal conductivity, corrosion resistant) |

| Copper thickness | 6oz (≈0.17mm, ± 10% tolerance) |

| Thermal conductivity | ≥2.0W/M · K (Aluminum Substrate Layer) |

| Thermal resistance | Solder temperature: 260 ° C/10S No delamination; Thermal cycling: 3 cycles (-40 ° C ~ 125 ° C) No cracks |

| Mechanical properties | Tensile strength ≥200mpa; Radius of the bend ≥1.5 × the thickness of the board (non-gyrulating side) |

| Final surface | Approved (AU thickness 0.05 ~ 0.1μm), OSP (Antioxidant) |

| Isolation layer | Epoxy/polyime (thickness of 50 ~ 150μm, dielectric strength ≥500V) |

| Min, width/space | 0.15mm/0.15mm (requires an electroplating process) |

6oz aluminum pcb for thermal management of electronic control boards

1. Material selection criteria

- Basic material: 6oz (170μm) aluminum PCB wrapped in copper with thermal conductivity ≥3w/m · k.

- Dielectric layer: Thermal resistance ≤1.2 ° C · cm²/w, voltage resistant ≥500V.

- Surface maintenance: finished anodized ≥5μm, surface roughness RA0.8-1.6μm.

2. The layout of the thermal source

- Maintain copper scope ≥30% in the high power zone.

- Save a distance ≥5mm between the components of the mosfet/IGBT.

- The position of the Sump-Sensi Sumper SIMS (capacitor) ≥10mm from the heat source.

3. Thermal path design

- Array through thermal under the critical component (0.5mm diameter, 1mm pitch).

- Through filling with the thermal conductive pasta (≥5w/m · k).

- Direct contact pressure ≥20n/cm² between PCB and housing.

4. Configuration of the cooling system

Passive cooling:

- Fit thickness ≥1.5mm, height ≥20mm.

- The thickness of the thermal oil 0.1-0.3mm in the interface.

Active cooling:

- Add axial fan during power density> 5w/cm²

- Air flow ≥3cfm/w, noise <35db (a)

5. Control process

- Soldering: Peak temperature 245 ± 5 ° C, reflow time ≤90s.

- Assembly: Stainless M3 screw (Torque 1.2-1.5n · M), spring washing ≥0.8mm.

6. Verification of performance

- Thermal resistance (intersection to ambient) ≤5 ° C/W.

- Increase in temperature ≤45 ° C below full load.

- Graduated 1000 hours 85 ° C/85% RH aging test.

7. The results achieved

- 40%+ increased heat dissipation efficiency.

- Reduction of 25-35 ° C in component operating temperatures.

- MTBF system ≥50,000 hours.

- Compliance with IEC 60068-2-78 Standard Heat Damping.

- 30%+ reduction of space compared to traditional designs.

6oz Electronic Control Aluminum PCB Making Process

1. Preparation of raw materials

- Procurement of electrolytic copper foil with high purity (6oz thickness, 210μm).

- Select the aluminum alloy 5052 or 6061 substrate.

- Prepare a high-conductivity-conductivity-conductivity dielectric layer (≥8W/MK).

2. Aluminum substrate pretreatment

- The surface of the Poland substrate mechanically to the surface roughness of RA ≤ 0.2μm.

- Chemically clean to remove surface oxide layers and oil contamination.

- Anodize to improve the nature of surface isolation.

3. The lining of the isolation layer

- Apply the thermal conductive adhesive uniformly using high precision coating equipment.

- Curing condition: 150 ± 5 ℃ for 30 minutes.

- Tolerance of thickness is controlled in ± 10μm.

4. Copper foil lamination

- Hot-Press Composite 6oz Copper Foil with an isolation layer.

- Process parameters: pressure 15-20kg/cm², temperature 180-200 ℃.

- Make sure there are no bubbles or delamination defects.

5. Transfer pattern

- Use LDI technology (laser direct imaging).

- Special ETSA compensation design needed for 6oz thick copper.

- Minimum width/distance: 0.2mm/0.2mm.

6. ETSA Process

- Adopt the meta solution of copper chloride acid.

- Control levels of the ETSA side strictly ≤15%.

- Deviation of post-etsa copper thickness in ± 10%.

7. drilling

- Use tungsten carbide drill or laser drilling.

- Tolerance of ± 0.05mm hole diameter.

- Hole wall roughness ≤25μm.

8. Surface is complete

- Optional Process: Gold Soaking/OSP/Hasl.

- Immersion gold thickness: 0.05-0.1μm.

- Nickel layer thickness: 3-5μm.

9. Printing of Solder Mask

- Apply high solder-solder-conductivity mask ink.

- Thickness: 20-30μm.

- Post-Cursus temperature resistance up to 150 ℃.

10. Contour machinery

- CNC mill with a contour tolerance of ± 0.1mm.

- V-Cut depth is controlled at 1/3 the thickness of the board.

- Talang to get rid of grinding.

11. Electric testing

- 100% Flying Probe Testing.

- Isolation resistance ≥1000mΩ.

- Resistant Voltage Test ≥3kv/60S.

12. Final Inspection

- Visual inspection under 10x magnification.

- Full dimensional inspection through CMM.

- Thermal resistance test ≤0.5 ℃/w.

13. Packaging & Delivery

- Vacuum humidity resistant packaging.

- Anti-gorean distance between each part.

- Storage Conditions: Temperature 15-30 ℃, Humidity ≤60%.

How do I balance the costs and quality of the electronic control aluminum PCB?

1. Optimization of tiering material

- Critical Zone: Use 6oz copper foil + 6061 aluminum alloy (thermal conductivity ≥200w/m · k) for high heat components (for example, IGBT).

- Non-critical zone: Distributing 4oz Copper Foil + 5052 Aluminum Alloy, reduces material costs by 15-20% while validating thermal distribution through simulation.

2. Standardization & Modularization of Design

- Build a universal circuit module library (for example, power conversion unit), cut special design time by 30%.

- Use the DFM system to automatically check the matches of the thermal expansion coefficient coefficient, reducing re -work by 67%.

3. Increasing Smart Manufacturing

- Distributing AI -powered visual inspection to monitor the uniformity of ETSA, increase the yield of 6oz 6oz copper boards from 85% to 96%.

- Adopt a diamond -coated milling cutter for edge processing, reducing the spurial rate by 90% and increasing the reliability of solder.

4. Vertical integration of supply chains

- Sign a long -term agreement with suppliers of raw materials to lock the price of copper foil; Use warehousing jit to cut the inventory fee of 10-15%.

- Prioritizing the isolation of domestic high conductivity (for example, epoxy filled with ceramics), shorten the lead time to ≤7 days.

5. Different surface finishing

- Apply low-cost OSP (preservative organic solderability) for non-coldering and enig areas for critical bearings, reduce surface maintenance costs by 40% while passing the RH test 500 hours 85 ℃/85%.

6. Accounting for life cycle costs

- Optimize for isolation of high conditions (≥8w/m · k): Although 20% more expensive in advance, this reduces the cooling component, cutting the total cost of the life cycle by 8-12%.

7. Manufacturing & Green Recycling

- Establish a memo recycling system (70% of the utilization of recycled aluminum), meeting the recycling target of EU 2025 EU 2025 (≥65%).

- Replace traditional stamps with laser cutting, reducing waste rates from 22% to 8% while increasing accuracy to ± 0.05mm.

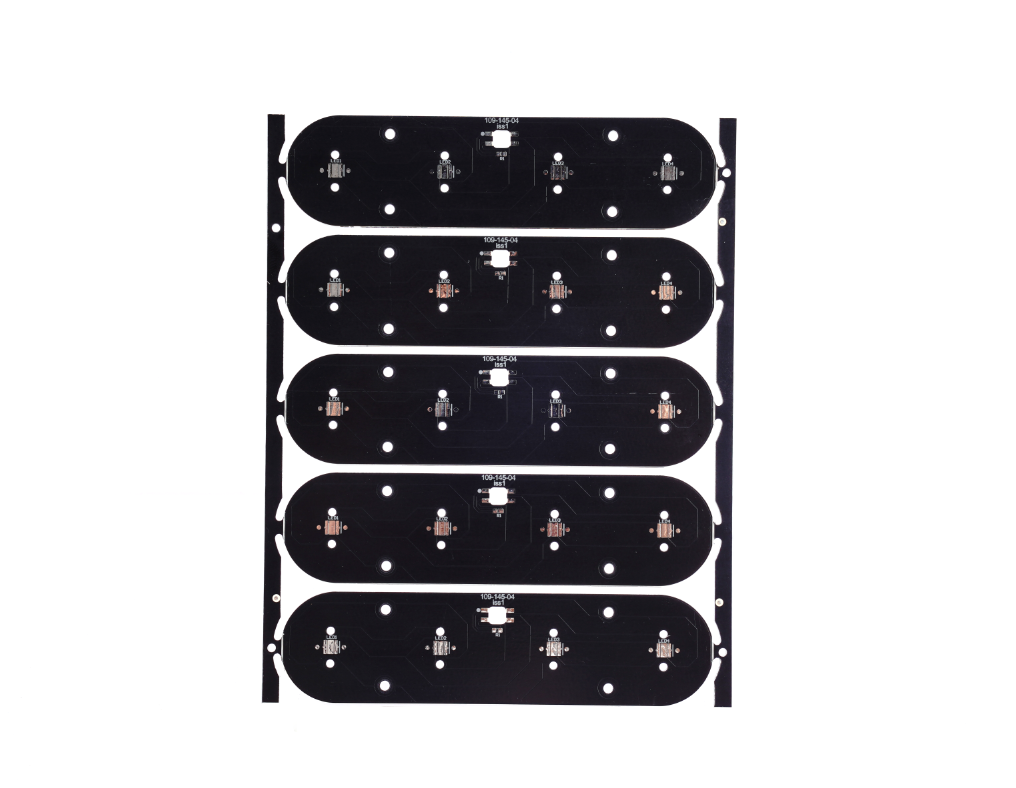

Case Study of Our PCB Aluminum Electronic Control

In the best technology, we specialize in the manufacturing of electronic control PCBs for 19 years, providing full services from design consultations to mass production. Our professional design team can adjust the design based on the layout of your power device and heat discipline requirements, ensuring your product meets strict electricity performance and mechanical stability requirements. This is a photo Electronic control board The PCB Aluminum that we made before:

Why choose the best technology as an aluminum PCB manufacturer?

Quality assurance of multiple certification

- ISO 9001 (General Quality) & IATF 16949 (Automotive Level) Certified

- Compliance with ISO 13485 optional medical level

Thermal Management Gradient

- Economy: 3W/M · K aluminum PCB for low -power devices (for example, security sensors)

- Premium: Aluminum Nitrida Substrate 8W/M · K For high power applications (for example, 5G base station)

Supply chain efficiency

- Sourcing directly reduces mass procurement costs by 15%-20%

- Flexible production scale from the prototype of 50 units to 10,000 mass production units

Fast Prototype 24 Hours

- Aluminum substrate samples are sent within 24 hours

- Optimization of DFM (Design for Manufacturing) free to reduce thermal risk through placement

Integrated One Roof Service

- PCB design, thermal simulation, and SMT assembly under one roof

- Engineering support for calculation of thermal resistance and modeling rise in temperature

Environmentally friendly manufacturing

- Rohs compliance with 95% recycled aluminum content

- Lead free process reduces carbon emissions by 25%

High airport material system

- Dielectric layer: ≥500V holds the voltage, ≤1.2 ° C · cm²/w Thermal resistance

- Anodized surface (5-8μm thickness), past 1,000 hours 85 ℃/85%RH aging test

Precision fabrication capability

- Minimum/distance trail width: 0.1mm

- Laser drilling accuracy: ± 0.05mm

- Precision Alignment Layer: ≤0.03mm

Welcome to contact us if you have a request for aluminum pcb: [email protected].

Tags: electronic control boards

This entry was posted on Friday, August 22, 2025 at 11:49 am and was submitted under the best PCB, BestTPCB, MCPCB, PCB Core Metal. You can follow any response to this entry through RSS 2.0 bait. You can jump to the end and leave a response. Pinging is currently not permitted.

Game Center

Game News

Review Film

Berita Olahraga

Lowongan Kerja

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Berita Politik

Resep Masakan

Pendidikan

Berita Terkini

Berita Terkini

Berita Terkini

review anime